Scavenger Unit (contactless solder removal) for H550 and HR550XL systems

- High-quality 400 W hot gas/ vacuum cartridge in suction head

- Spacious solder collecting tank

- Process gas cleaning

- Integration possible in HR 550 or HR 550 XL

- Process control via HRSoft 2 and clearly arranged operating elements

Machine enquiry

- OVERVIEW

Ersa SCAVENGER – contactless residual solder removal for HR 550 and HR 550 XL

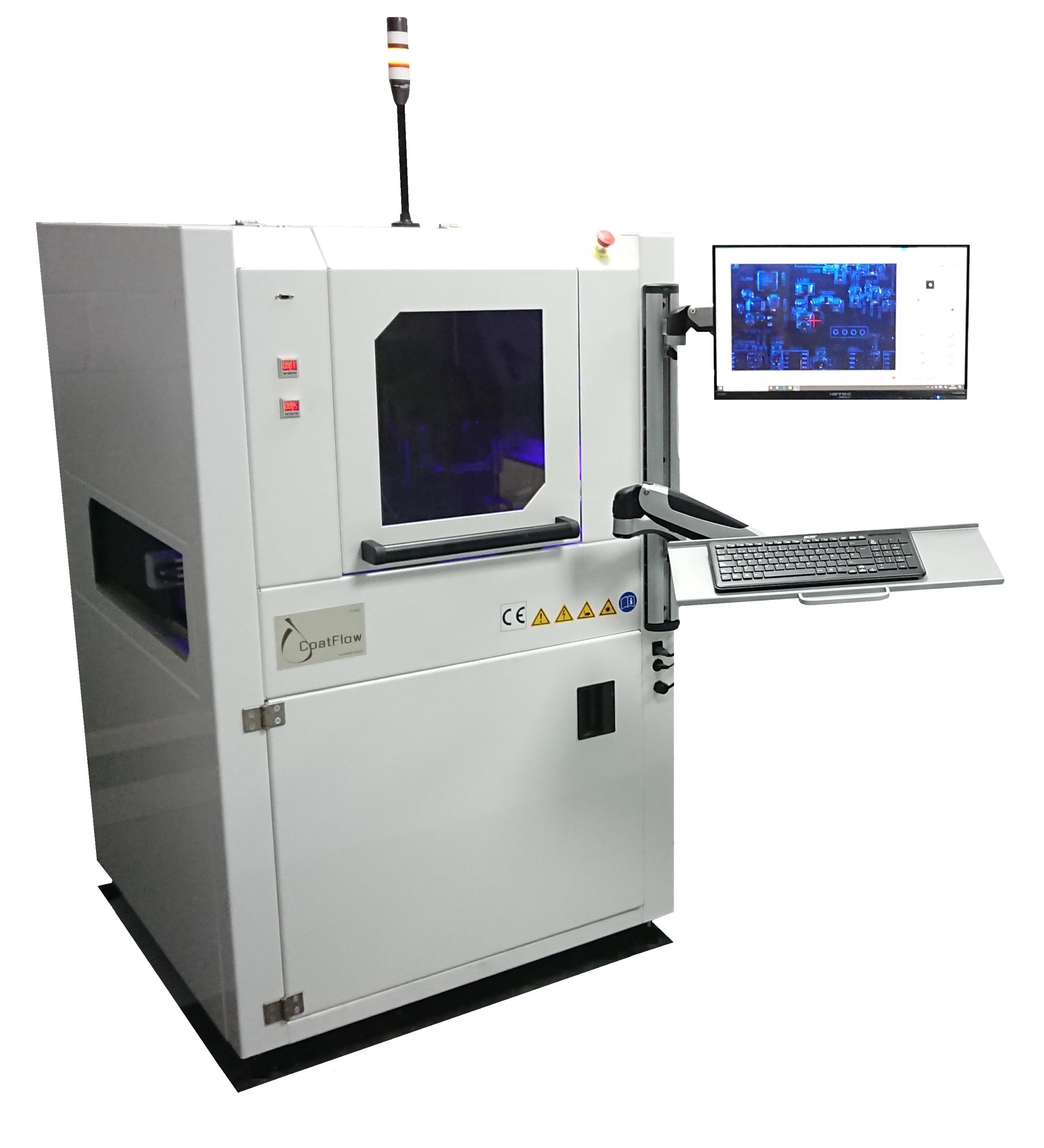

The Ersa Hybrid Rework Systems HR 550 and HR 550 XL offer semi-automatic repair of SMT components at the highest level. With the Ersa SCAVENGER, both systems can be additionally equipped with a non-contact residual solder extraction system.

The separate module is coupled with the Ersa Rework System and allows to gently and safely clean the connection areas on the PCB from residual solder.

After a desoldering process, the suction head of the SCAVENGER is swivelled into the working position and the suction nozzle is lowered to just above the board. The board is kept at temperature by the bottom heating of the rework system. The solder is re-melted with the help of precisely metered hot gas and immediately sucked off. When operating the HR 550 or HR 550 XL with a SCAVENGER module, the process step “remove residual solder” is inserted and the user is guided through the individual actions. On the HR 550, the board is moved under the suction head manually, on the HR 550 XL motorized with a joystick. For both rework systems the connection of an Ersa EASY ARM 1 solder fume extraction system is recommended. The solder fume is extracted close to the solder joints.