Automatic Scavenger Unit for HR600 and HR600XL models

The Ersa HR 600 XL Hybrid Rework System offers automatic repair of SMT components at the highest level. Equipped with the Auto Scavenger, HR 600 XL removes the solder that remains on the PCB surface after desoldering the component without any physical contact.

The retrofittable module is fully integrated in the HRSoft 2 software and is used on the HR 600 XL after the desoldering process. The bottom heater of the rework system automatically keeps the assembly at temperature. The top-side hot gas head gently remelts the residual solder in the specified area so that it can then be extracted by vacuum via the exchangeable nozzles. An automatic height control ensures that solder extraction is performed without any contacts of the nozzle with the PCB surface.

For optimum extraction results, the user sets the extraction parameters individually for his application. After the residual solder has been removed, the assembly is ready for the installation of a new component.

Machine enquiry

- OVERVIEW

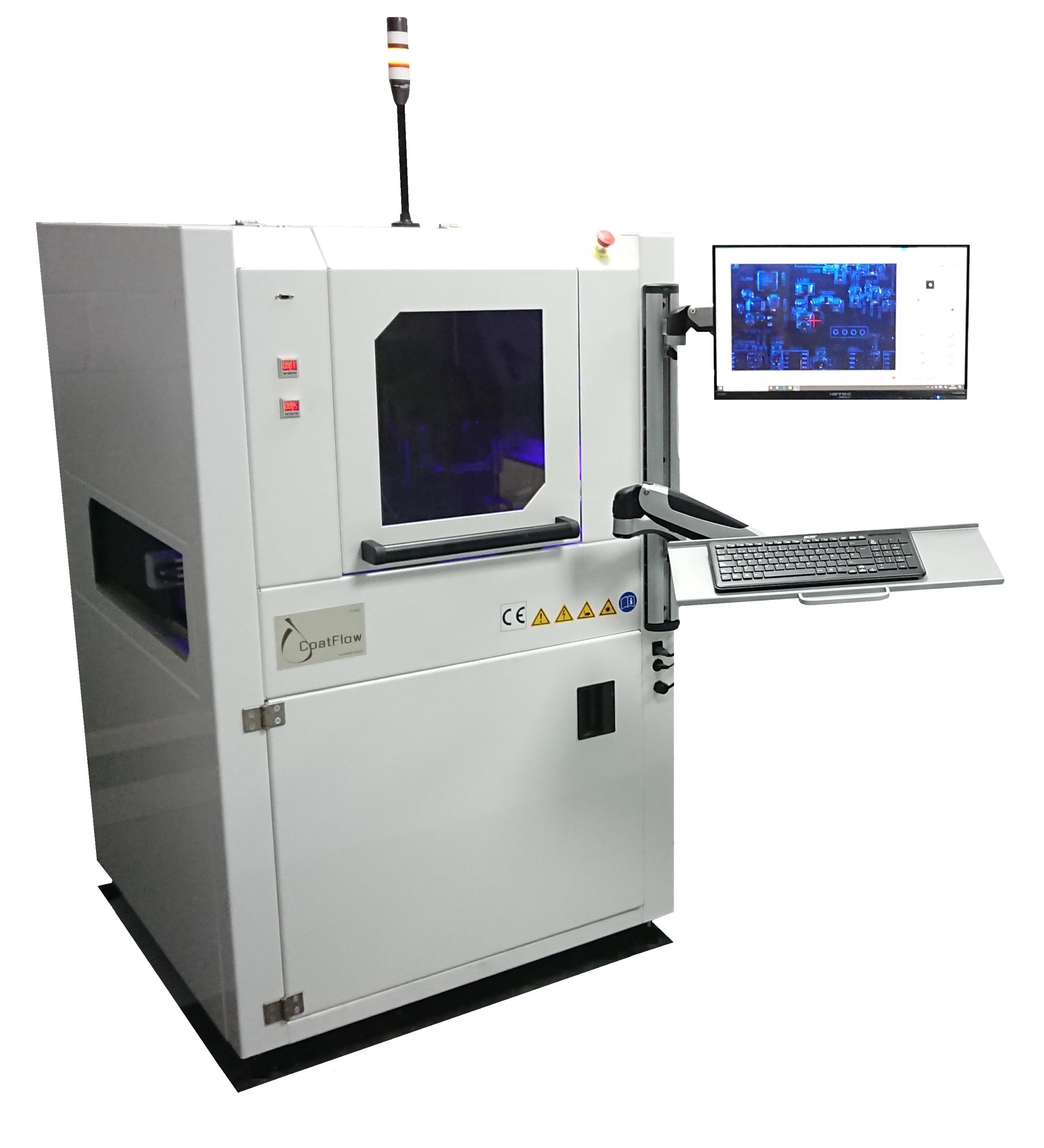

Auto Scavenger Module for HR600XL

- Automatic height adjustment

- Automatic track definition

- Individual setting of extraction parameters

- Operation using N2 as protective gas

- Available as an option or retrofit kit for all HR 600 XL systems