placeALL® 520

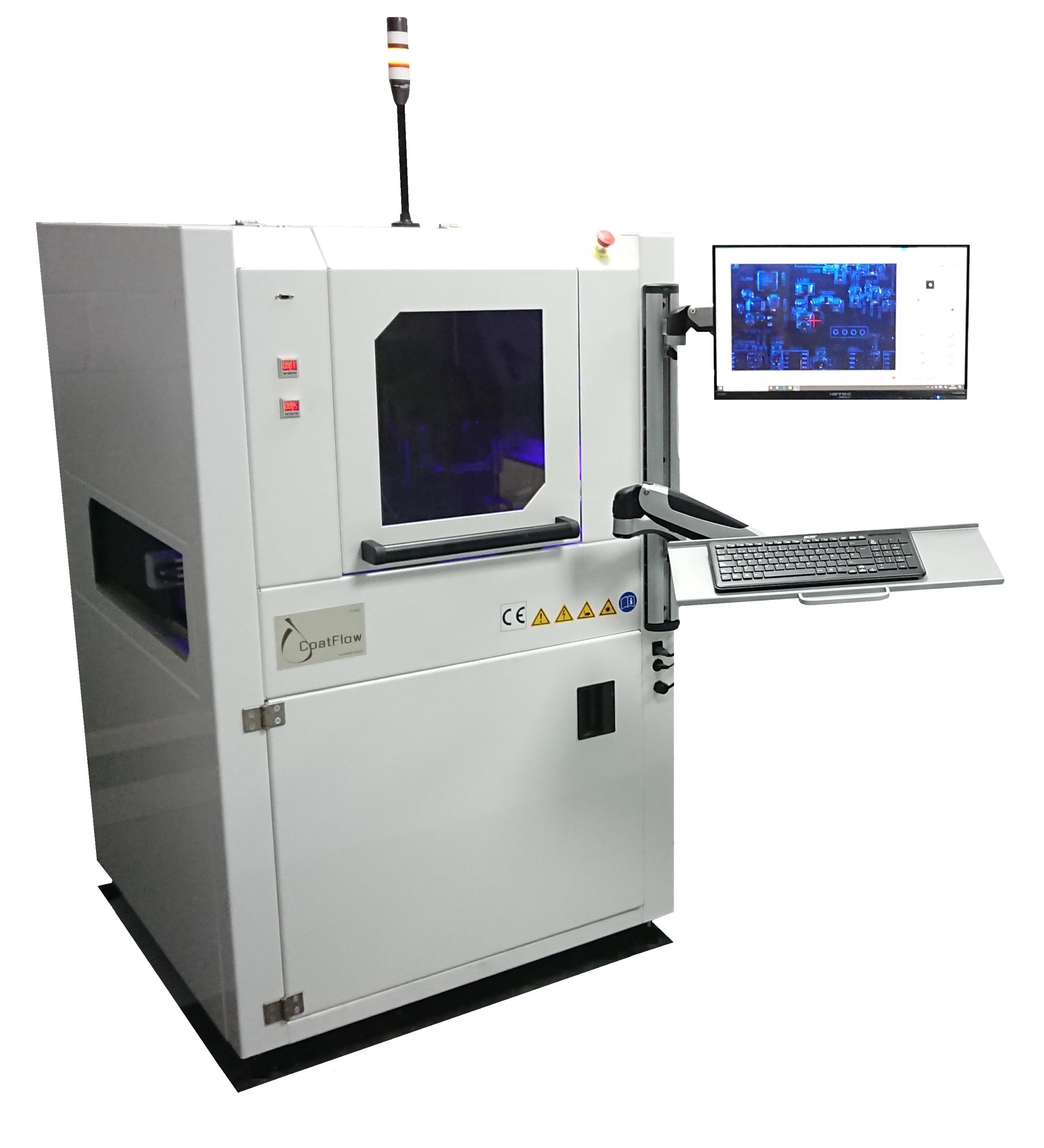

The PlaceALL® 520 is a modular Pick&Place system and especially useful to build prototypes and small series. It supports a large range of components (chips, FP-components and BGAs), so even the most complex tasks can be handled.

Machine enquiry

- OVERVIEW

PlaceALL PA-520

An intelligent software and up to 200 possible kitting slots minimise changeover times, which increases productivity for small lot sizes.

The placeALL® 520 can easily be upgraded or integrated into an inline system on location.

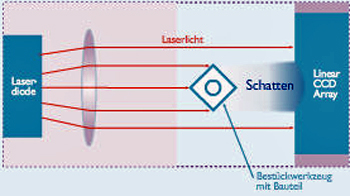

Laser centering

The patented CyberOptics laser centering uses a laser diode to project a beam onto the component. By rotating the part and analyzing the resulting shadow length, the component is aligned.

The centering mechanism is mounted directly to the assembly head and aligns the components when the head is moving from the pickup to the placement step.

The laser centering can handle components from 0402 chips up to 30×30 mm in size and 0.5 mm in pitch.

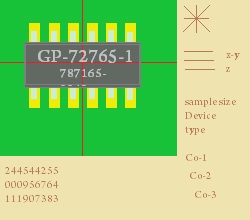

Optical centering

To align components like FP / BGA / CSP / µBGA or custom parts up to 50×50 mm and a pitch of 0.4 mm, the stationary camera system is used.

It measures each pin or outside edge and calculates the corresponding correction factor.

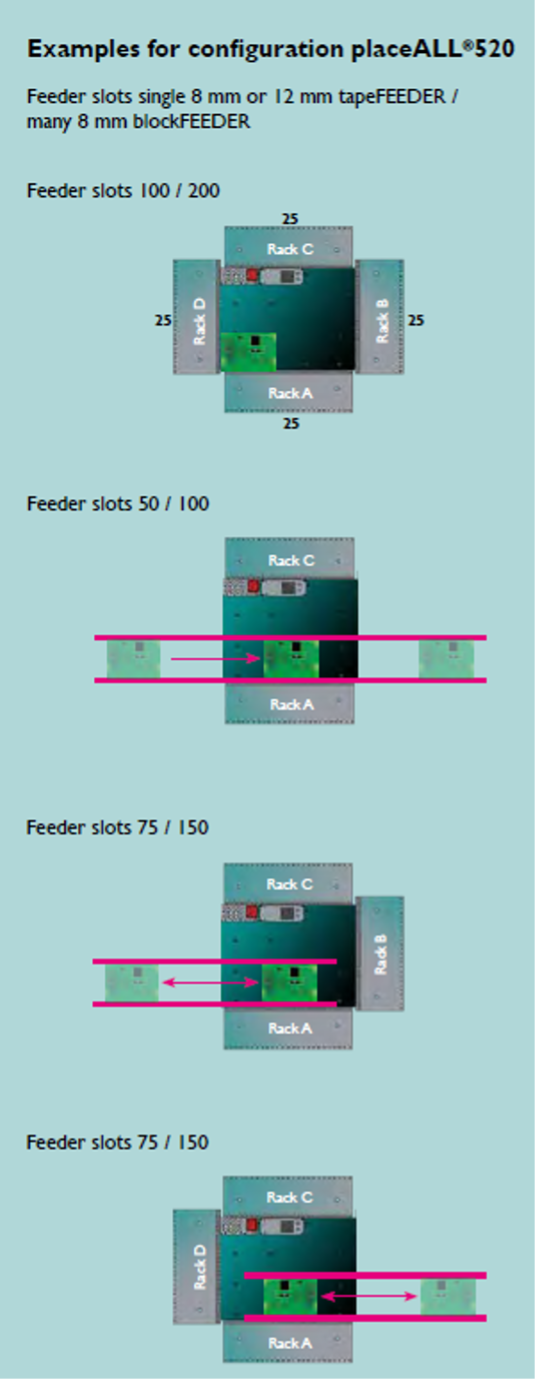

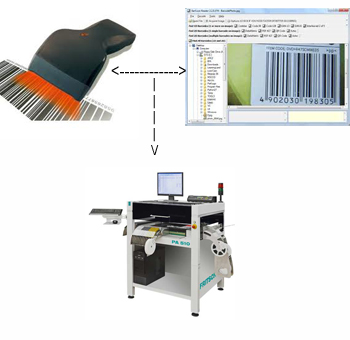

smartFEEDER®

smartFEEDER®’s are intelligent feeders, that are equipped with a microprocessor control. Using a wireless barcode reader, reel- and feeder-barcode are programmed and saved in the software. The placeALL® Pick&Placer has now knowledge about the amount, type and position of the feeder. Thus changeover times between different projects are greatly reduced.

Automatic fiducial recognition

This extension recognizes the fiducials on a circuit board by itself. This is especially useful for inline systems. The position correction is done using a dot, cross, rhomb etc. on the circuit board.

While assembling multi-boards, single circuit boards – which are marked by the producer – can be excluded.

Teach In

If no CAD data is available to create a new assembly project, each position can be taught manually.

Therefore the component is displayed and aligned virtually. After reaching the right placing position on the monitor, it is approved and automatically added to the assembly project.

CAD data converter

With the universal CAD data converter, you can import data from all common CAD programs in a few simple steps.

To ensure a high machine load on the Pick&Placer, the corresponding data files can be prepared using our offline software version on a separate workstation.

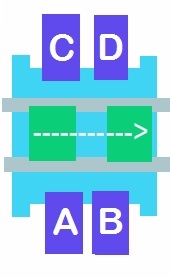

Inline – system

A classic production line can be built using our inline transport system. This includes chaining of reflow ovens, automatic Pick&Placers and transfer units like loaders. Controlling works acording to the SMEMA-Standard.

The inline transport system can be installed at any time on location.

Dispensers

Dispensing of solder paste or glue can be done with two different systems:

• Time-pressure system

For dispensing big solder paste dots or glue

• Microprocessor-controlled system

This system detects parameters like cartridge temperature, fill level etc. . It can dispense amounts from 0.001 to 10 mm³. By this Fine-Pitch components down to a pitch of 0.5 mm can be safely dispensed, the ideal solution for prototypes.