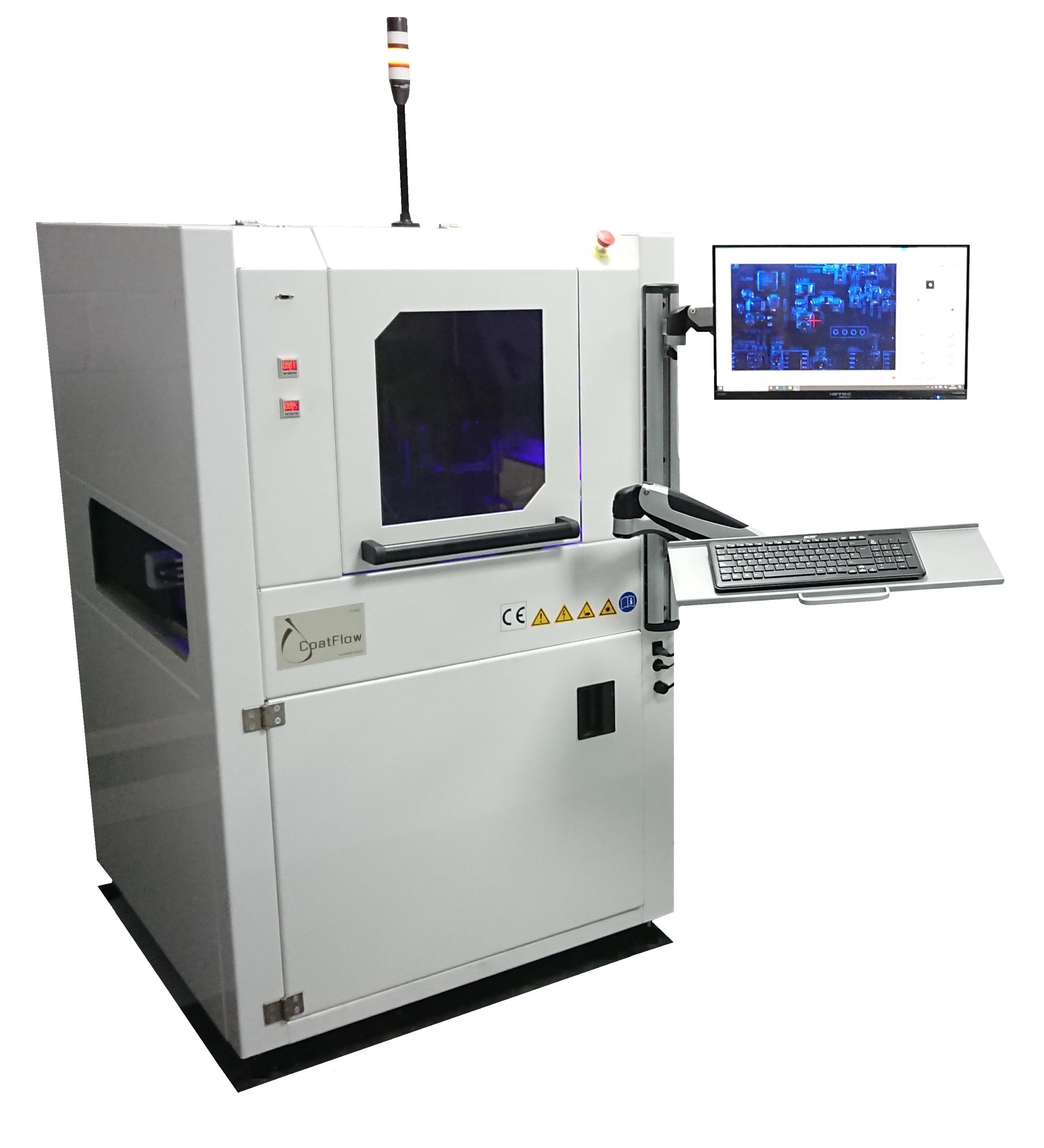

placeALL® 620

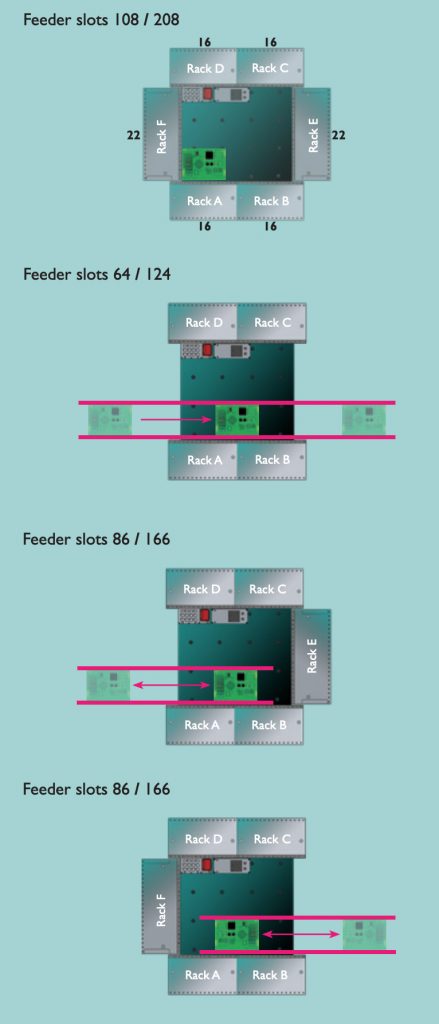

Like the placeALL®520, the placeALL®620 has a modular structure and is used for the production of small series up to medium lots. The range of components from chips up to type 0201, FP components and BGAs up to grid 0.3 mm and max. 70 x 70 mm outer dimensions can be processed safely. An optional 2nd placement head can even increase production by up to 40 %. 208 possible feed positions and intelligent software reduce the machine setup. The “smartLINE” combination with dispensing or other automatic placement machines not only increases the feeder capacity but above all the output of the machine.

Machine enquiry

- OVERVIEW

SMD fully automatic Pick & Place system

with one Pick & Place head with lasercentering for 0201 chips up to 22 x 22 mm (alt. up to 32 x 32 mm) pitch 0,6 mm

placement speed up to 6000 (4600 / IPC9850) cp/h max. 108 slots – 208 feeder positions for reel 8 mm

max. placement area: 620 x 450 mm

board table: 520 x 370 mm

placement area adaptably configureable

Range of applications

Pick & Place and dispensing of small series up to medium lot sizes

Feeding units Feeding of components as tape, stick, tape-strip, tray and loose components

Integration of customized feeders is possible

Feeding units

Feeding of components as tape, stick, tape-strip, tray and loose components

Integration of customized feeders is possible

Features

- standalone or inline

- dividable machine frame

- max. 2 Pick & Place heads

- max. 2 dispensing heads

- RCL component test up to 0201

- vacuum table for flexible circuits