Miniswash

Cleaning solder paste from any type of stencils, screens and printer squeegees

Removing SMT Glue residues from any type of stencils, screens or PumpPrint stencils

Defluxing, removing all kinds of soldering residues from high density PCBs

Cleaning contamination from handling and board manufacturing

Cleaning second side misprints on complex assemblies

×

Machine enquiry

- OVERVIEW

- VIDEOS

Unique Features

- Fully automatic spray-in-air closed loop zero drain system

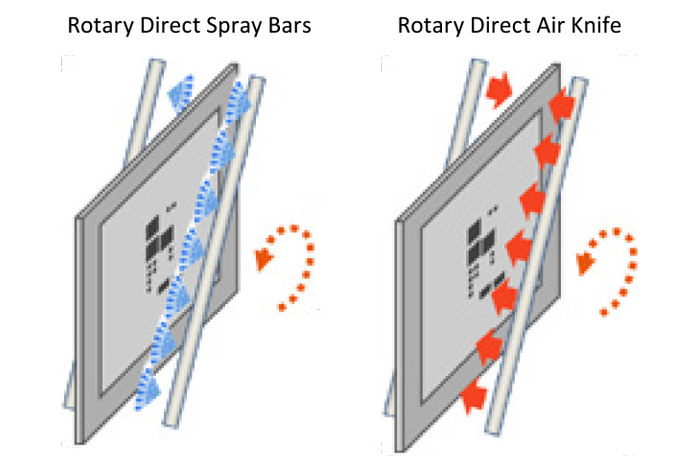

- Synchronous, double-sided, constant speed motor-driven nozzle manifold

- Hot air knife direct dry technology

- Anti-collision system

- Synchronized motion check

- Compatible with wide range of chemistry from various suppliers

- Heating in cleaning medium, optionally in rinsing

- Clamping for all types of stencils and squeegees

- Advanced adjustable frame fixing system

- Wide range of PCBA fixtures

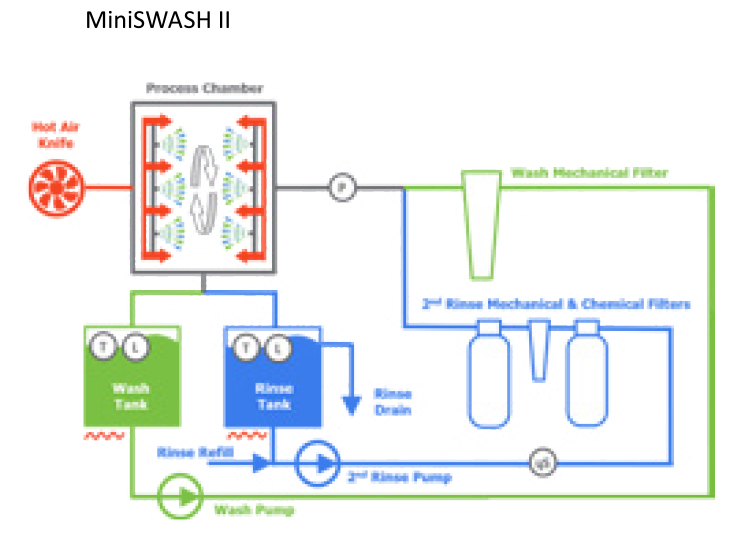

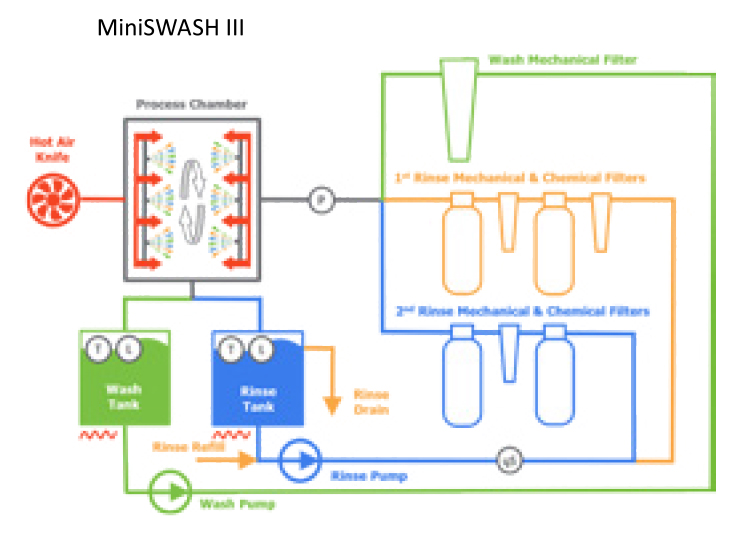

- Two fully separated liquid loops, up to 2-step rinsing

- Low consumption of chemicals and water

- Outstanding options of water utilization

Control Features

- Intuitive touchscreen interface

- PLC control

- Full barcode traceability, LAN connectivity

- Unlimited recipe library

- Adaptive rinse process control for stable quality

- Multi language selection

Capacity and Size Options

- Single – single frame

Filtration Options

- Easily connected to water supply and drain

- External filter carts with up to 25l mixbed and 25l active carbon

- Optional double rinse

Clamping Options

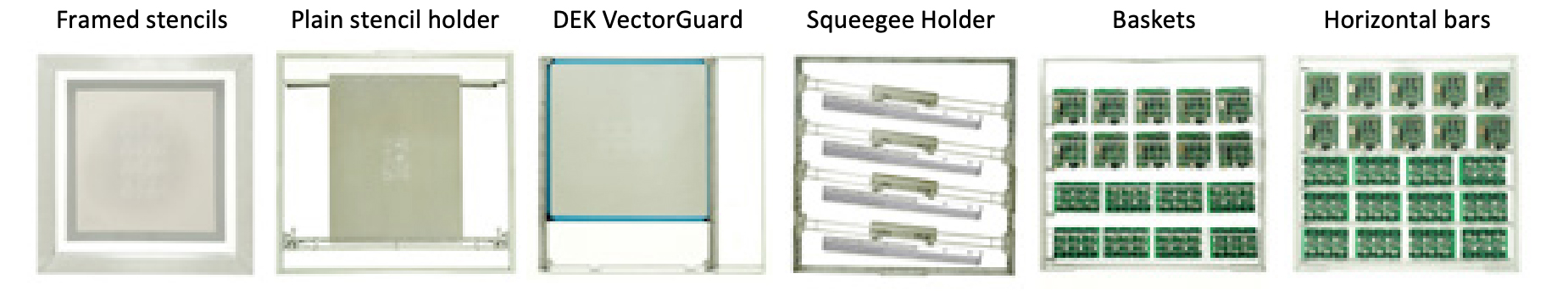

Conventional framed stencils and screens fit directly into the built-in adjustable clamping

Wide range of standard fixtures and adaptors for other types of stencils and PCBAs

Customization is available for any clamping fixtures

Versions by Application

- MiniSWASH I Wash + Dry stencils, screens, squeegees, PumpPrintTM stencils

- MiniSWASH II Wash + Rinse + Dry PCBA, stencils, screens, misprints, squeegees, PumpPrintTM stencils

- MiniSWASH III Wash + Double Rinse + Dry PCBA after soldering, PCBA before coating