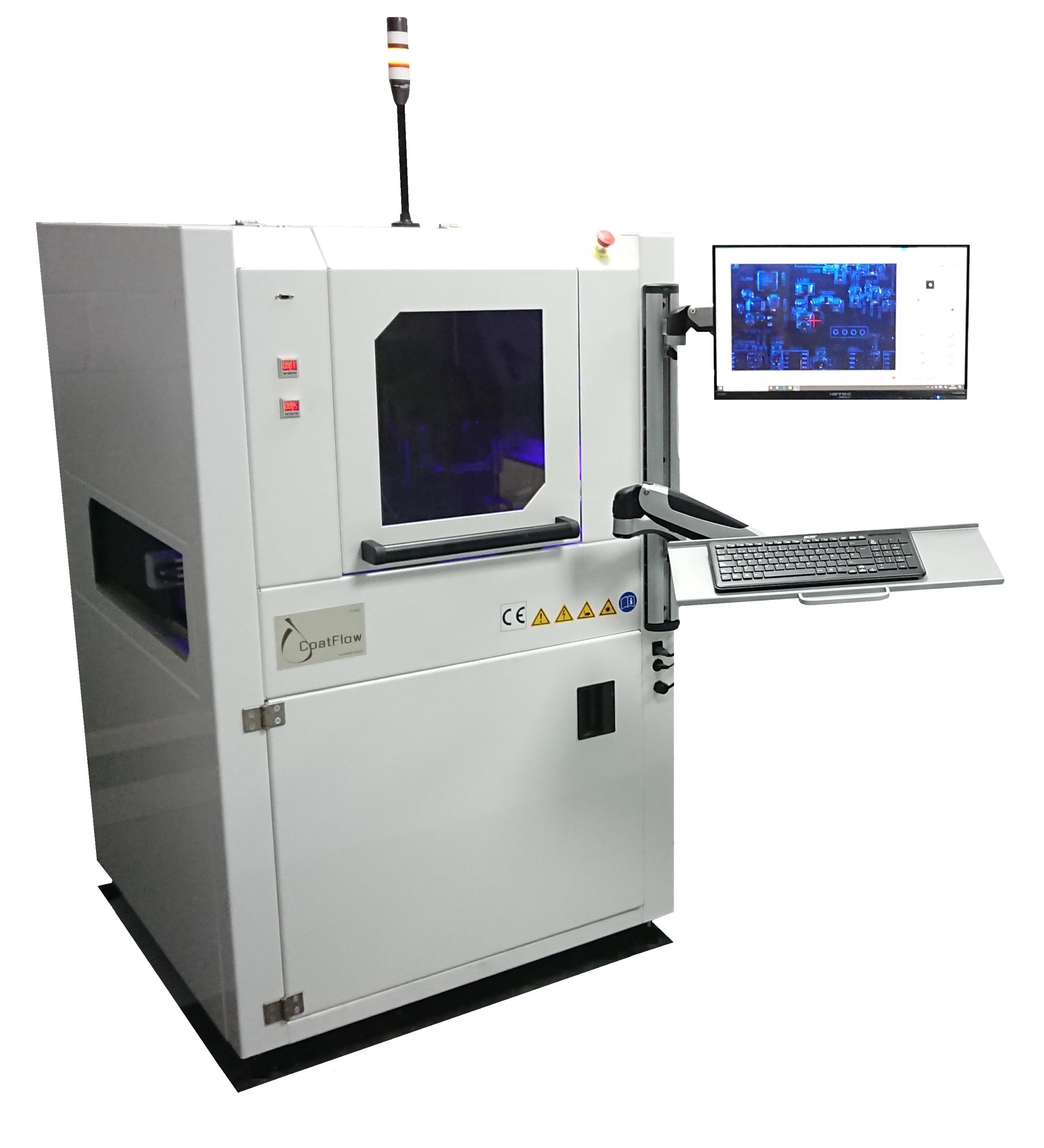

Hyperswash

- Defluxing – removing all kind of solder residues

- Cleaning of micromechanical components

- Cleaning contamination from handling and board manufacturing, removing FOD

- Highly populated electronic assemblies with low standoff components such as BGA, CSP, BTC, QFN, MELF

- Cleaning of power electronics

- Electronic assemblies requiring extra short process time

- Second side misprints on complex assemblies

- Cleaning before conformal coating and wire bonding

×

Machine enquiry

- OVERVIEW

- VIDEOS

Unique Features

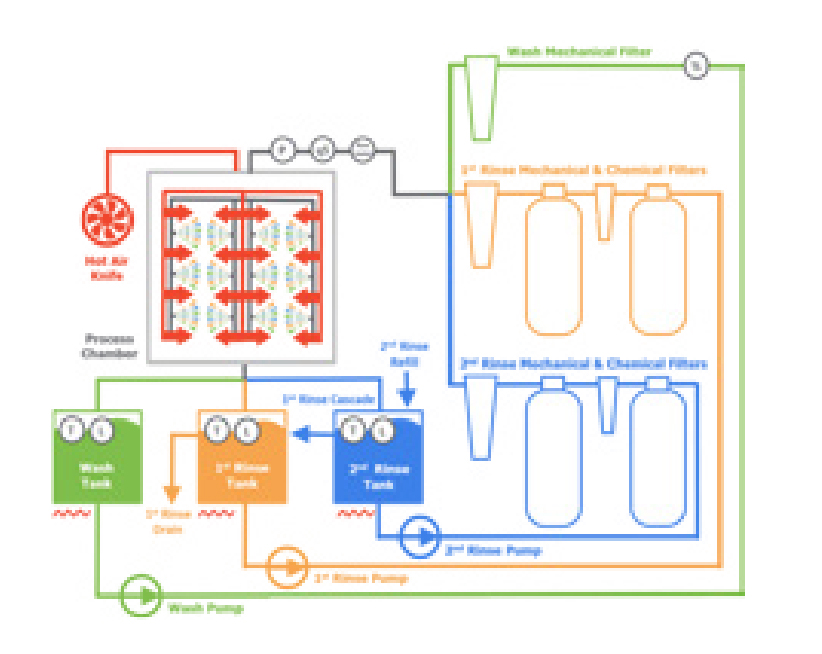

- Fully automatic spray-in-air closed loop zero drain system

- Double capacity configuration TWINGO

- Multiple capacity in COMBO configuration

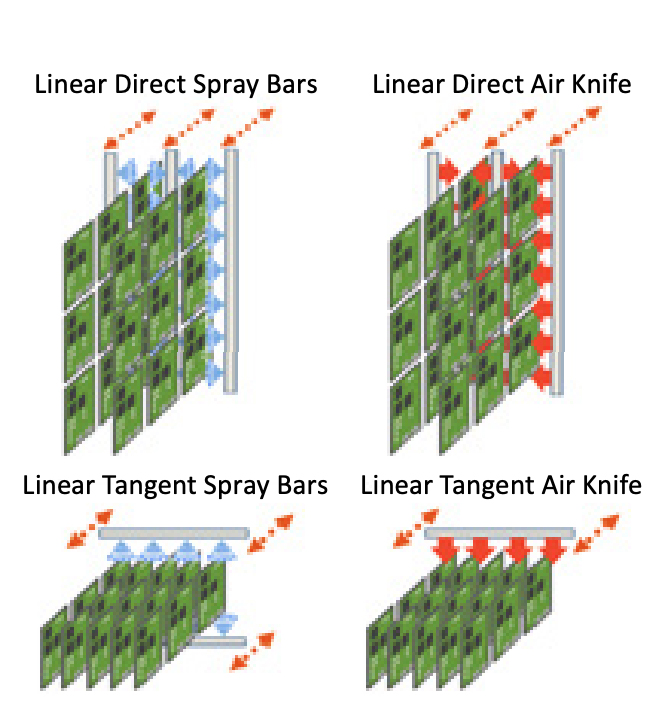

- Linear direct spray for equal washing of entire surface

- Compatible with wide range of cleaners from various manufacturers

- 100% filtration of entire spray volume

- Two separate rinse loops

- Possible to use two different cleaners

- Hot air knife direct dry technology

- Illuminated glass door chamber for visual process control

- All process steps with up to 5 substeps for the highest flexibility

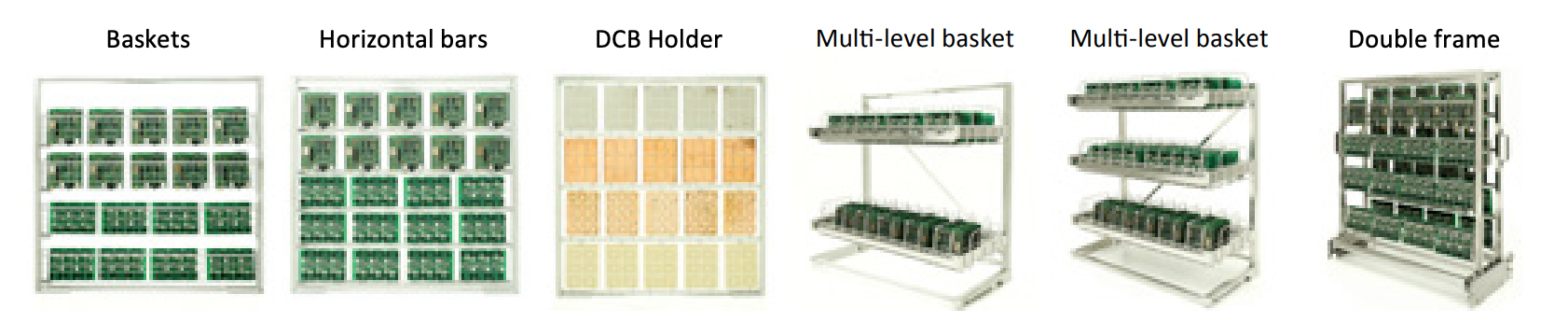

- Wide range of standard and customized PCBA fixtures

- Clamping for all types of stencils

- 3 separate liquid loops with possible cascade in rinse loops

- Low consumption of chemicals and water

- Proportional level sensors in all processes

Control Features

- Intuitive touchscreen interface with Windows OS

- SPC for all parameters in graphical interface – trends, limits

- Adaptive rinse water quality control

- AAD Automatic adaptive cleaner dosing with concentration sensor ZESTRON® EYE or KYZEN ANALYST™, integrated in machine OS

- Dosing of up to 2 additives

- Complete datalogging, LAN connectivity

- Bar code traceability

- Unlimited recipe library

- Personalised password security

- Multi language selection

Capacity and Size Options

- Single – single frame

- Twingo – double frame

- Combo – multi-level basket

- Modification between options in 10 minutes

- Custom designed nozzle system available

Filtration Options

- Zero drain concept – close loop, cascade or open loop can be set by software only

- Special filtration strategy for the highest flow

- First rinse filtration fully separated from second rinse filtration

- External carts with up to 39l of mixbed and 39l active carbon

Clamping Options

- Wide range of standard fixtures and adaptors for any types of PCBAs and stencils

- Customization is available for any clamping fixtures

- Adapter for framed stencils

Versions by Application

- HyperSWASH Wash + Rinse I + Rinse II + Dry PCBA after soldering, PCBA for coating, power electronics, micromechanics