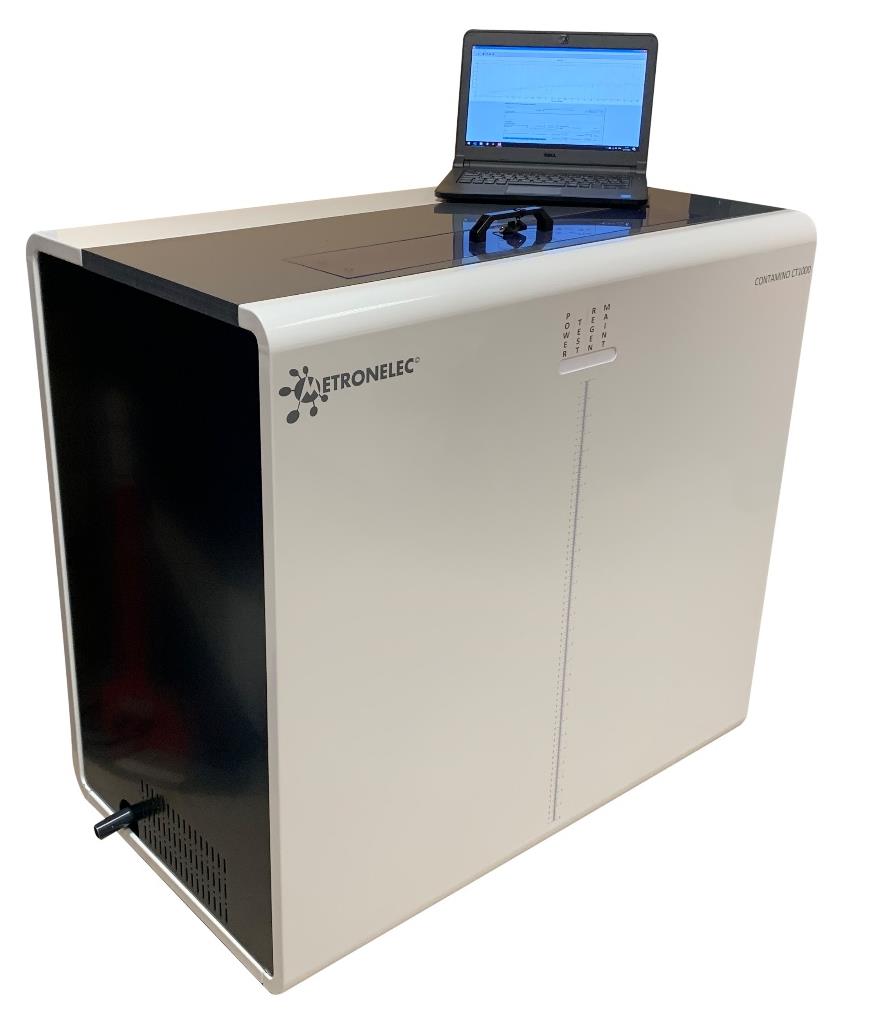

Ionic Contamination Tester

The Contamino range is designed to make simple and accurate ionic contamination test on electronic boards fully complying with MIL, DEF, IPC and IEC Standards.

These measures are necessary to check the cleanliness of boards and assemblies after cleaning, or in case of new solder process parameters (no clean process, conformal coating, lead free alloy with new activator), for quality control and approval.

In humid atmosphere, the ionic contamination is transformed in electrolyte catching moving ions which can create failures on electronic assemblies (dendrites, bad insulation).

Machine enquiry

- OVERVIEW

The ionic contamination test will point out these risks, secure accordingly assembly process and will extend life duration, reliability of end product.

During the test process the specimen is first cleaned thoroughly using 2-Propanol and de-ionized water (75/25 or 50/50) while analyzing continuously contamination development in the cleaning solution which is running in closed loop tubing.

The measurement process is computer controlled. The operator enters the characteristics of the sample and introduces it into the tank after a regeneration phase. The rest of the test is automatic, the measurement is carried out according to the time requested, giving the evolution of the contamination over time. The test solution is regenerated for each measurement by a filtering system offering a level of conductivity of the solution well below specifications before testing. This system consists of a long-life ion exchange resin filter (one liter capacity per cartridge).

The solution is circulated by a powerful, maintenance-free pump and a set of solenoid valves to switch between the regeneration and test circuits.

The conductivity measuring cell used is a very high precision cell compensated by an integrated temperature probe.

The choice of this cell was made in close collaboration with a world leader specialist in conductivity trace measurement.

This measuring set has a very good sensitivity in the order of 0.0001 μS / cm which offers the possibility of detecting very low contamination, even on samples with small surfaces.

The special performance of the probe allows the use of a larger cell size, while maintaining good precision, avoiding cell changes depending on the size of the samples. Standard dimensions of the tank: see table above. The range is also designed to be easily adapted to all sizes of circuits, from the smallest to the largest.

The results are shown according to standards in microgram equivalent NaCl per cm² of circuit in the form of contamination levels at a given time. The multilingual software has all the classic archiving functions for perfect traceability.

Multitasking, it is also possible to work on curves while taking a measurement.

Norms and standards used for ionic contamination testing:

- Mil-P-28809 et Mil-STD-2000A (USA)

- Defense Standard 10/03 (UK)

- IPC TM 650; IPC TR 583