BPE supply a comprehensive range of soldering equipment, including both vapour phase and convection reflow ovens. As leading suppliers within our industry, we are often asked if there is any conflict between these two technologies. The simple answer is no, as vapour phase equipment is generally used for running smaller batches of high valve, complex PCBs, while convection ovens are typically used for higher throughput processes. In fact, many of our customers have invested in IBL Vapour Phase machinery to run alongside their Convection ovens.

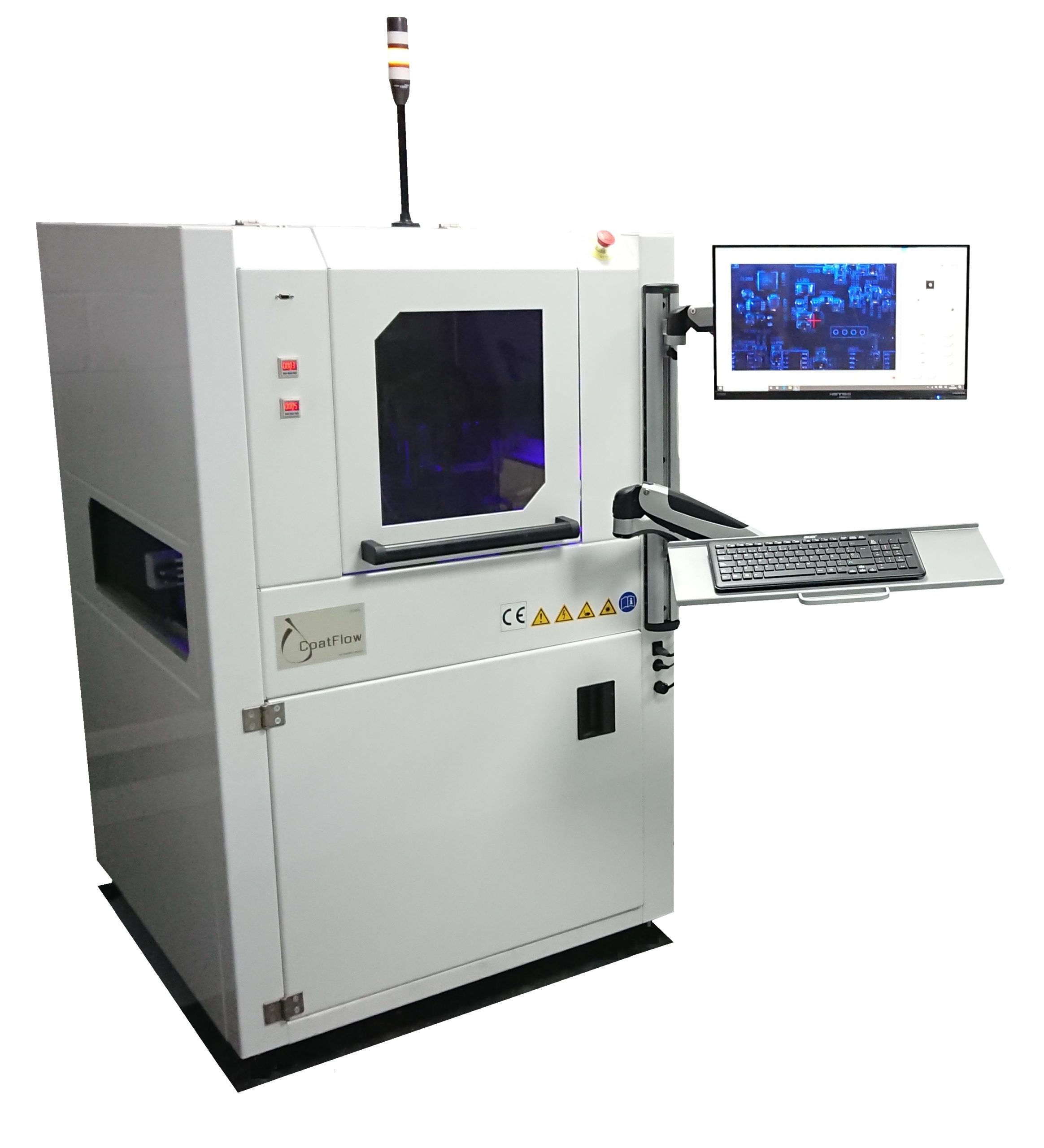

Vapour Phase Reflow