Hybrid Rework Station

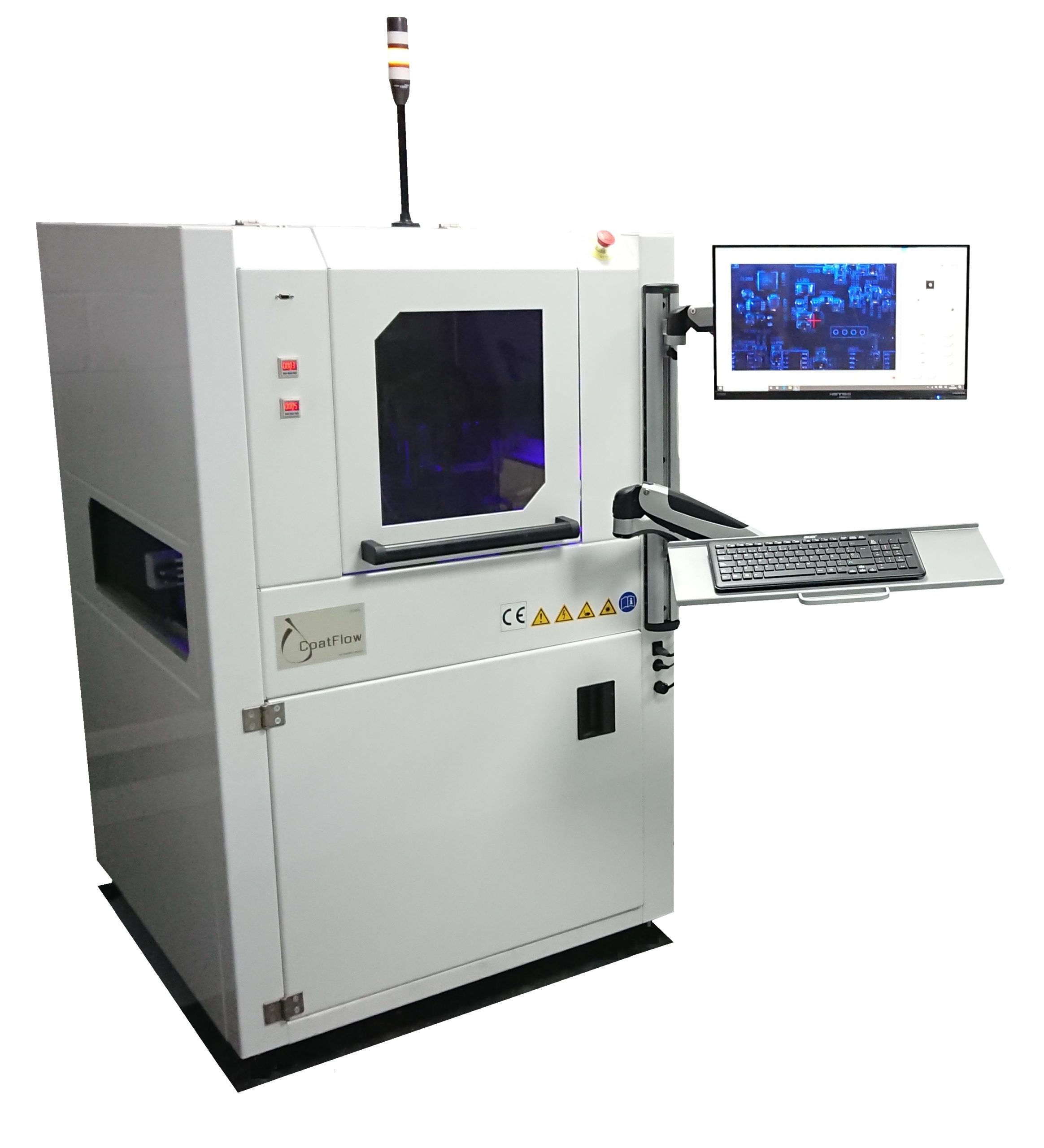

Blundell are the leading suppliers & distributors of industrial production machinery across the UK, providing bga machine and hybrid rework station equipment to a number of companies from diverse sectors of industry. These machines are among some of the best that exist, and their top-quality performance is highly regarded within the hybrid rework station arena.

Our distributors are leading in the field of BGA rework station machinery, providing customers with a range of quality solder rework station equipment, including bga rework station and ir rework station options.

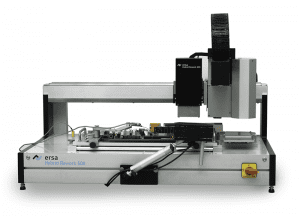

Ersa’s rework machine spectrum is extensive and offers total solutions no matter how large or small. From simple hand tools to automated rework systems there is a machine within the Ersa range.

Browse Blundell’s BGA rework equipment range, or make contact with the team for any questions relating to rework stations.