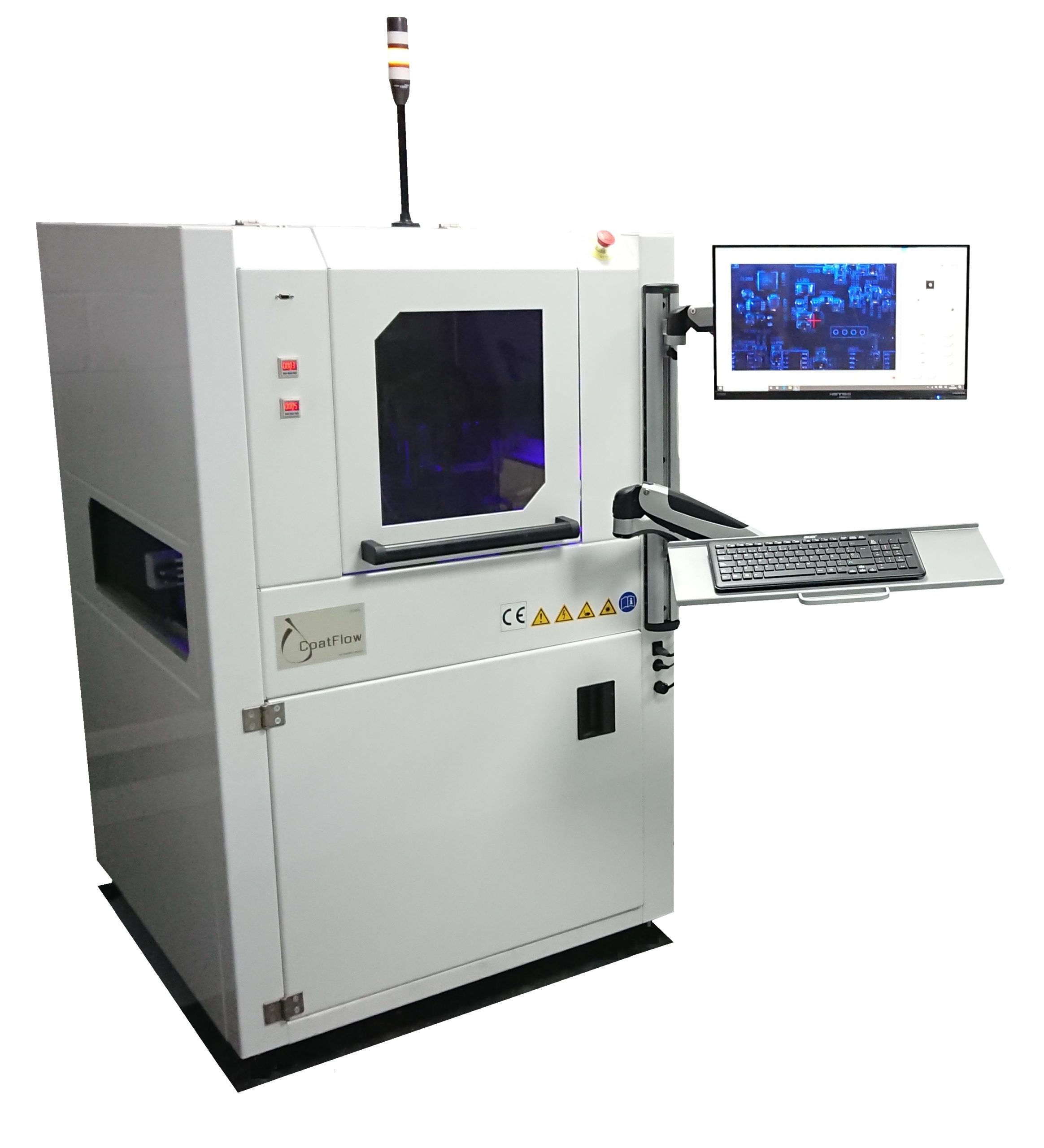

HR 600/2

Technical Highlights:

- Highly efficient 800 W hybrid heating head

- Homogeneous, large-area IR bottom heating with 3 heating zones (800 W each)

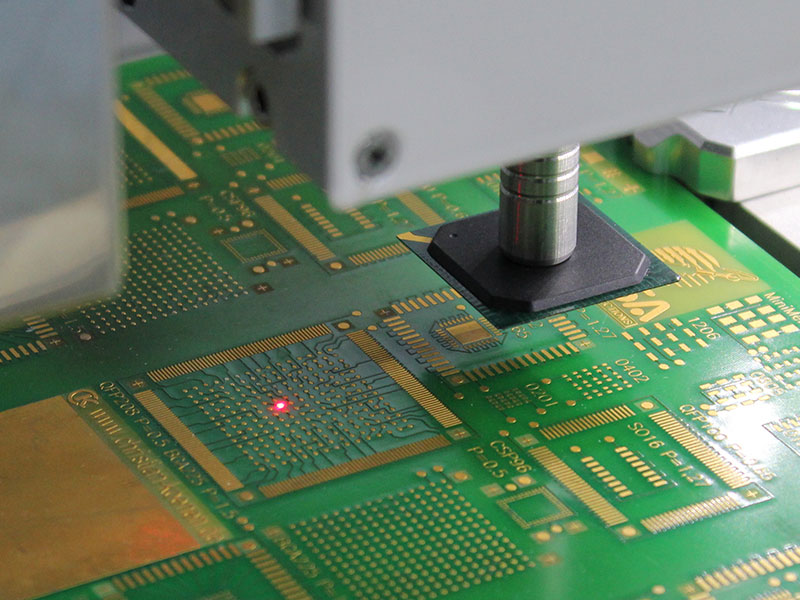

- Automatic and precise component alignment with the help of machine vision

- Highly accurate, motor-driven axis system

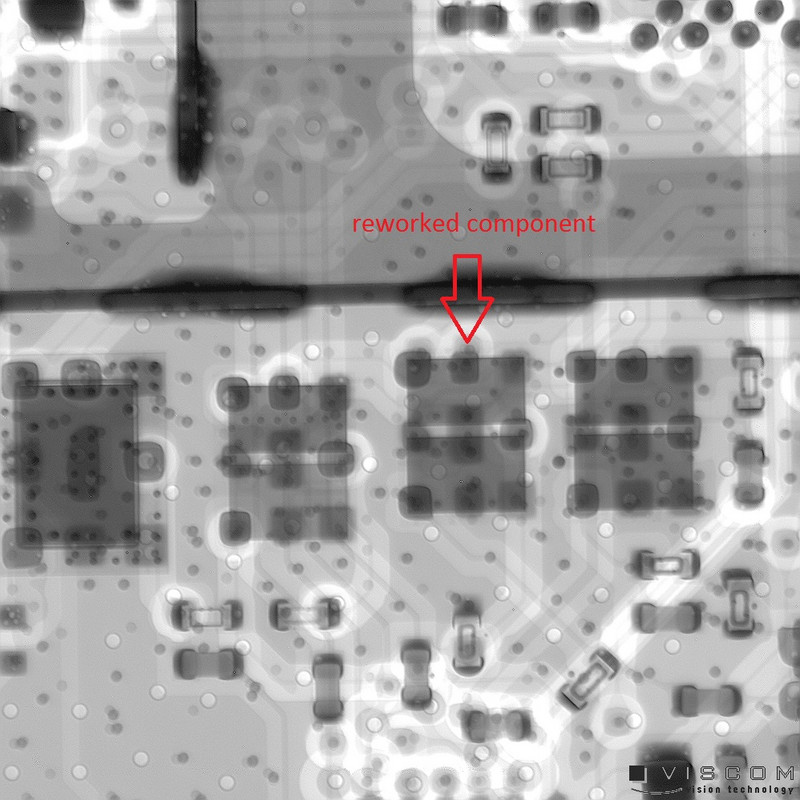

for component placement (+/- 0.025 mm) - User independent, reproducible repair results guaranteed

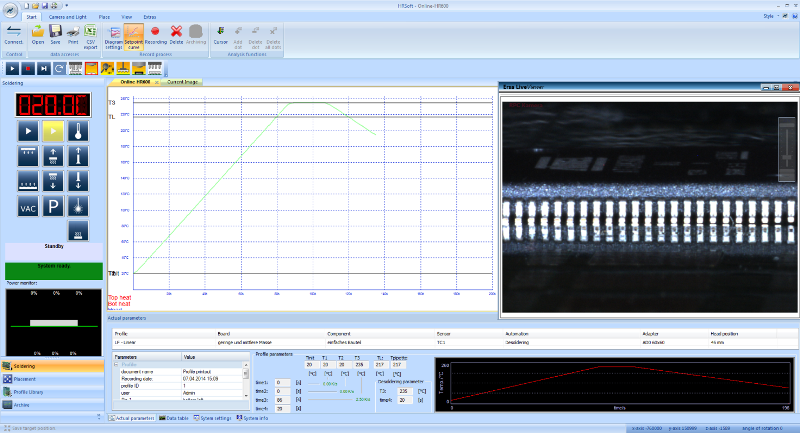

- Process control and documentation via the operator software HRSoft

- Fully automatic or semiautomatic operation

- Suitable for the use of the Dip&Print Station

×

Machine enquiry

- OVERVIEW

- DOWNLOADS

- VIDEOS

| Technical Data | |

|---|---|

| Dimensions (W x D x H) in mm | 850 x 660 x 620 |

| Weight in kg | 57 |

| Antistatic Design (y/n) | y |

| Power Rating in W | 3,200 |

| Nominal voltage in V AC | 230 |

| Compressed air connection | 6-10 bar (free of oil), 1/4 inch quick bar connect |

| Volume of air cooling | approx. 65 l/min (@ 6 bar) |

| Upper heating | Hybrid emitter (2 x 400 W), 60 x 60 mm |

| Lower heating | IR emitter (3 x 800 W), 380 x 250 mm |

| PCB size in mm | up to 535 x 300 mm (+x) (0HR600/2L) |

| Component size in mm | from 1 x 1 to 50 x 50 |

| Operation | Windows PC |

| Test symbol | CE |

| Option | reflow process camera: 10 MP CMOS USB color camera, 25 mm focal width; lighting: 2x LED point light source, dimmable |