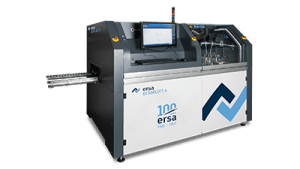

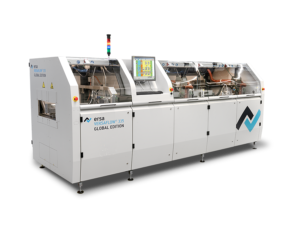

VERSAFLOW 3/45

The first inline selective system with double transport – highly flexible

- Highest throughput in the entire selective soldering market

- Most sold selective machine platfoem worldwide

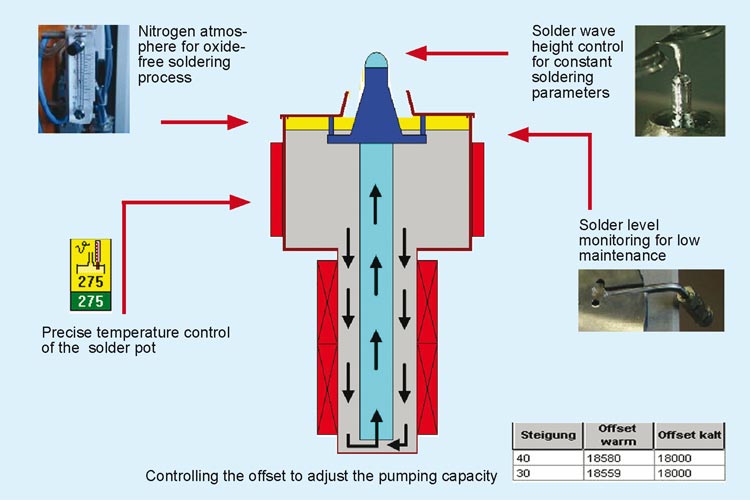

- Safe process control with monitoring of all relevant parameters

- Full modularity – suitable for every customer requirement

Machine enquiry

- OVERVIEW

- DOWNLOADS

- VIDEOS

High Volume with Dual Transport Option

The new VERSAFLOW 3/45 is the world’s first in-line selective soldering machine with dual track transport and ERSA’s proven single wave solder nozzle technology for highest flexibility and highest volume throughput for two each PCBs sized up to 508 mm x 204 mm (20″ x 8″).

Parallel processing

With up to 4 individual single wave solder nozzles and 8 flux heads running simultaneously, the VERSAFLOW 3/45 boasts the world’s fastest throughput.

Modular machine Platform

The VERSAFLOW 3/45 encompasses a new modular machine platform which offers a floor space area savings of over 20% when compared to the previous VERSAFLOW machines.

Additional solder pots, fluxers and/or pre-heat modules can be added to the machine after initial installation.

Depending on the specific job requirement, pre-heat configuration or total length of the machine can be varied in order to ensure optimum efficiency and maximum workflow flexibility.

Top side multijet convection heating technology extends the process flexibility for the pre-heating of high mass assemblies, and finally, the improved serviceability at front end of machine rounds off the added value of the new design.

- Fully Automated Selective SolderingIn-Line Capability

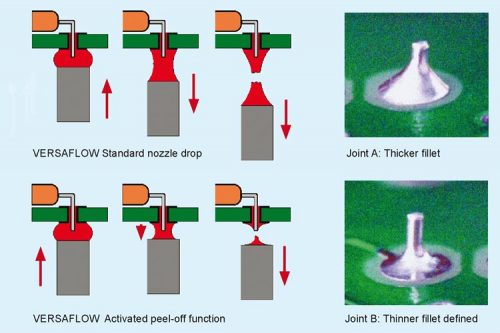

- High Flexibility For Quick Job Changeover

- Ideal For High Mix Production

- Moving Solder Bath On X-Y-Z Axis

- Robotic Pin-Point Spray Fluxer

- Conveyor Fed Pcb LoadingUnderside And Topside Pre-heaters

- Barcode reader option

- CAD download programming facility

- Process observation camera

- Double solder bath version available for high volumes.