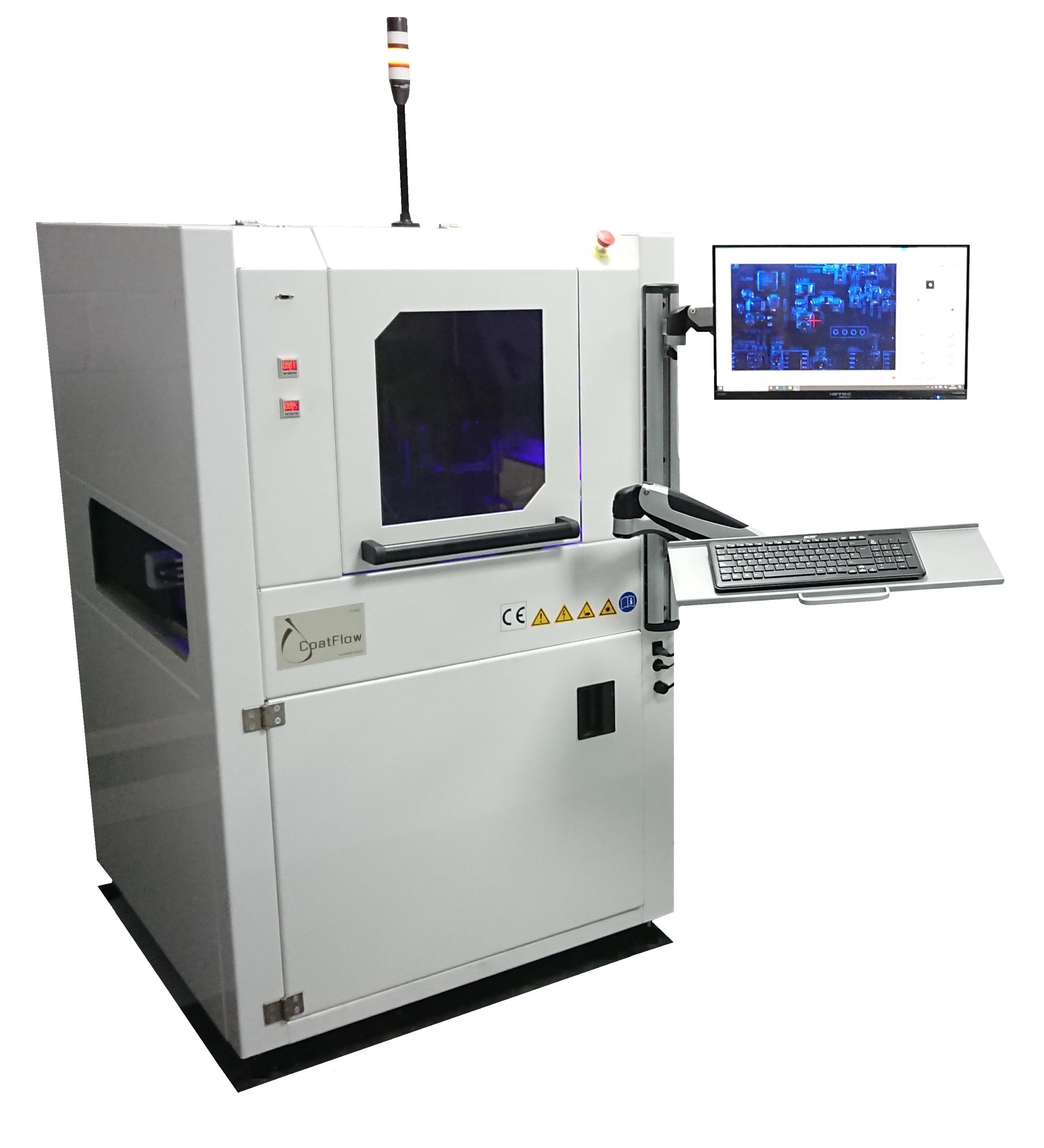

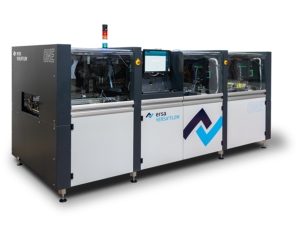

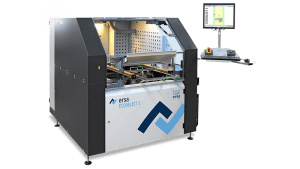

Ersa SmartFlow 2020

‘The little big one among the selective soldering systems: uncompromisingly compact.

- “Plug and Solder” – the compact selective entry model

- Intuitive operating concept

Machine enquiry

- OVERVIEW

- DOWNLOADS

- VIDEOS

The little big one from Ersa in selective soldering: compact without compromises, extremely smart! Winner of the GTI Award 2015.

As a leader in selective soldering technology, Ersa has expanded its range of products in this sector by a compact selective soldering system. The SMARTFLOW has a smaller footprint than its predecessors and as a batch system and is equipped with the very latest technology to make for simple and effective operation.

The SMARTFLOW manages with an area barely more than what would be required for a modern hand soldering work station. It is thus perfect as an entry-level system or for smaller productions. With the SMARTFLOW large printed circuit boards with dimensions up to 20 x 20“ (508 x 508 mm) can easily be manufactured.

Individual User Interfaces

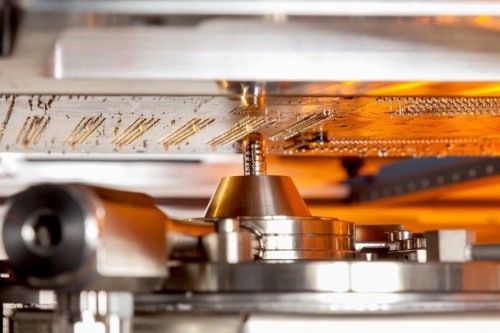

Just like all the selective systems from the house of Ersa, this machine is also equipped with the low-maintenance and wear-free solder pot with induction pump and has all-over preheating, which can be segmented depending on the heat requirement and assembly size. The reliable Ersa high-precision spray flux system is also used here.

This new version of our time-tested machine software impresses with its user-oriented structure in addition to modern visualisation. Thanks to individual user interfaces, every user group gets the required data and information at a glance. The new interface is also convenient when it comes to process monitoring.

- Loading & unloading at same position

- Flux Head and Solder pot are mounted on one Y Z Axis

- The board will be clamped and then moved on X

- The preheating is fixed and heats up the entire PCB

- For heavy mass PCBs – Optional top heater

- Compact without compromises

- Modern process visualisation with ERSAsoft 5

- Convenient PC control with swiveling 24” touch-screen

- Ersa CAD-Assistent

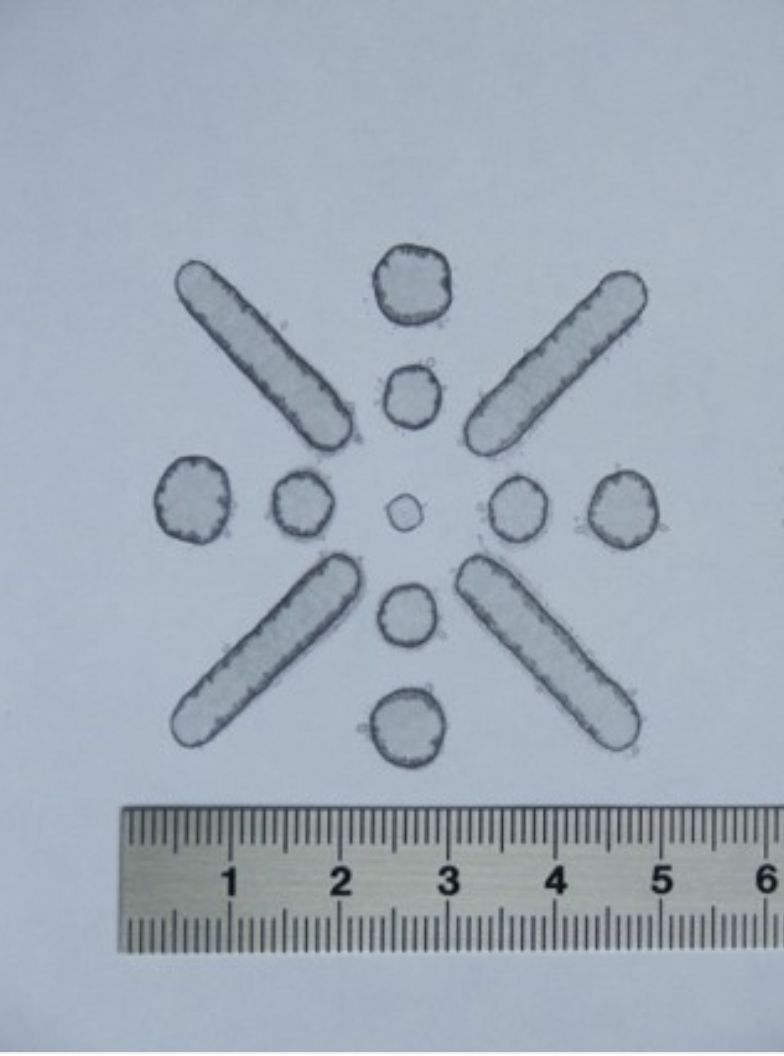

- Use of Mini-Vario-Wave, Mini-Dip and area nozzles

- High ease of servicing

- Drop-Jet Fluxer with integrated monitoring

- Highest positional accuracy and process

- All-over heating IR preheating lower/upper (scalable)

- Low energy and N2 consumption