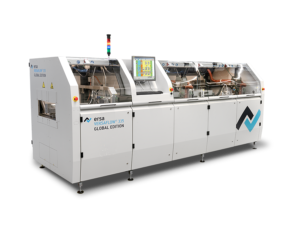

Ersa Ecoselect 4

Inline and batch selective soldering system for highest selective quality

- Ready for the Future: Upgradeable flexible inline soldering system with VERSAFLOW 4 technology

- Intuitive operating concept

- Highest process reliability due to proven control systems

Machine enquiry

- OVERVIEW

- DOWNLOADS

- VIDEOS

The Ecoselect-4 is a compact system that is perfectly suited for small to medium-sized batches where flexibility is essential, featuring machine technology of the latest VERSAFLOW generation.

Its conveyor system is a high-quality roller conveyor offering a max. PCB size of 508 x 508 mm and can be used inline or in batch operation.

Another machine highlight is the new power convection heating, for example, which provides an optimal, homogeneous warm-up for complex boards. Like all Ersa selective soldering systems the it is equipped with a programmable precision spray fluxer with integrated spray control for precise and economical flux application in single spots or in tracks. A second spray head is available as an option.

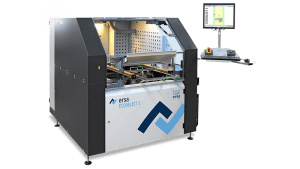

Innovative machine operation with ERSASOFT 5

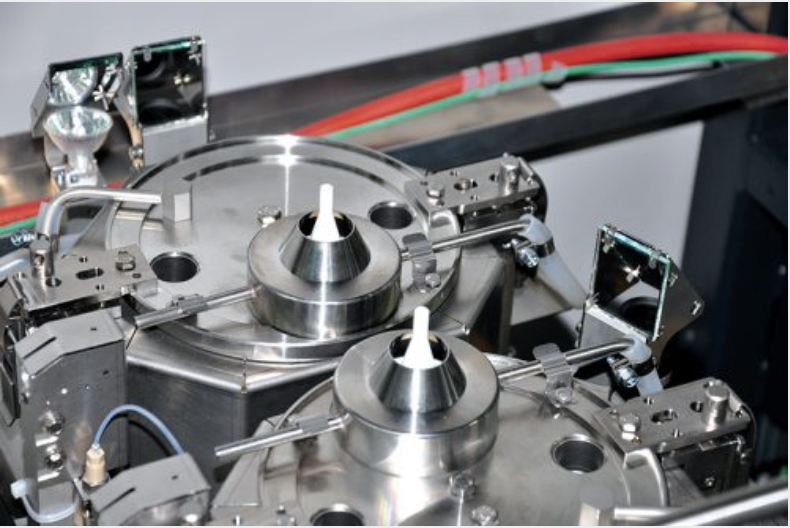

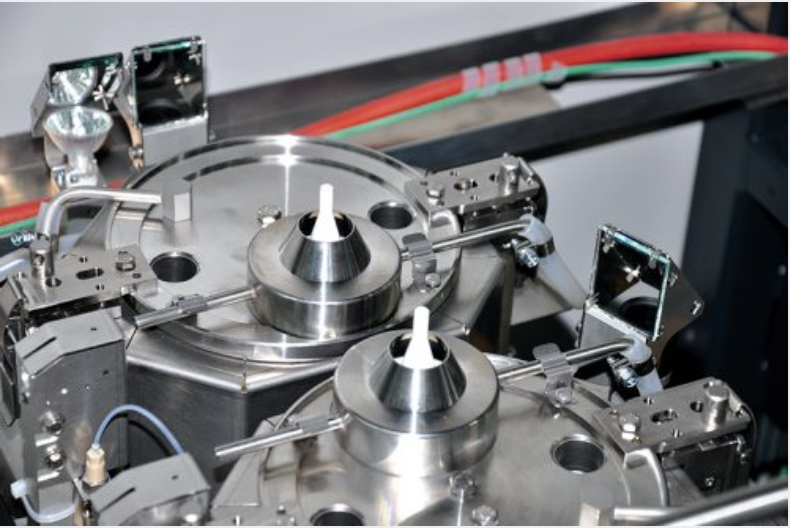

The new dual solder pot system of the VERSAFLOW 4 is also available for the ECOSELECT 4.

Both mini wave pots can be moved flexibly in Y/Z direction. Thus the machine operator can install solder nozzles with different diameters in order to quickly solder connectors or multi-pin devices with a large diameter nozzle while also having access to a very slim nozzle shape for joints which are difficult to reach.

The innovative and user-friendly ERSASOFT 5 software makes the machine operation even more intuitive. Through individual user interfaces, each group of operators receives, at a glance, the data and information required.

A further software highlight is the PiP technology (picture in picture) combined with a process monitoring camera.