Ultra Electronics selective soldering

Ultra Electronics upgrade to ERSA selective soldering

Contract Electronics Manufacturer Ultra Electronics has a Global presence in heavily regulated markets. They manufacture for mission critical applications where safety and reliability matter within market sectors such as aerospace, defence, oil and gas, mass transportation, automotive, nuclear energy, security and scientific instrumentation

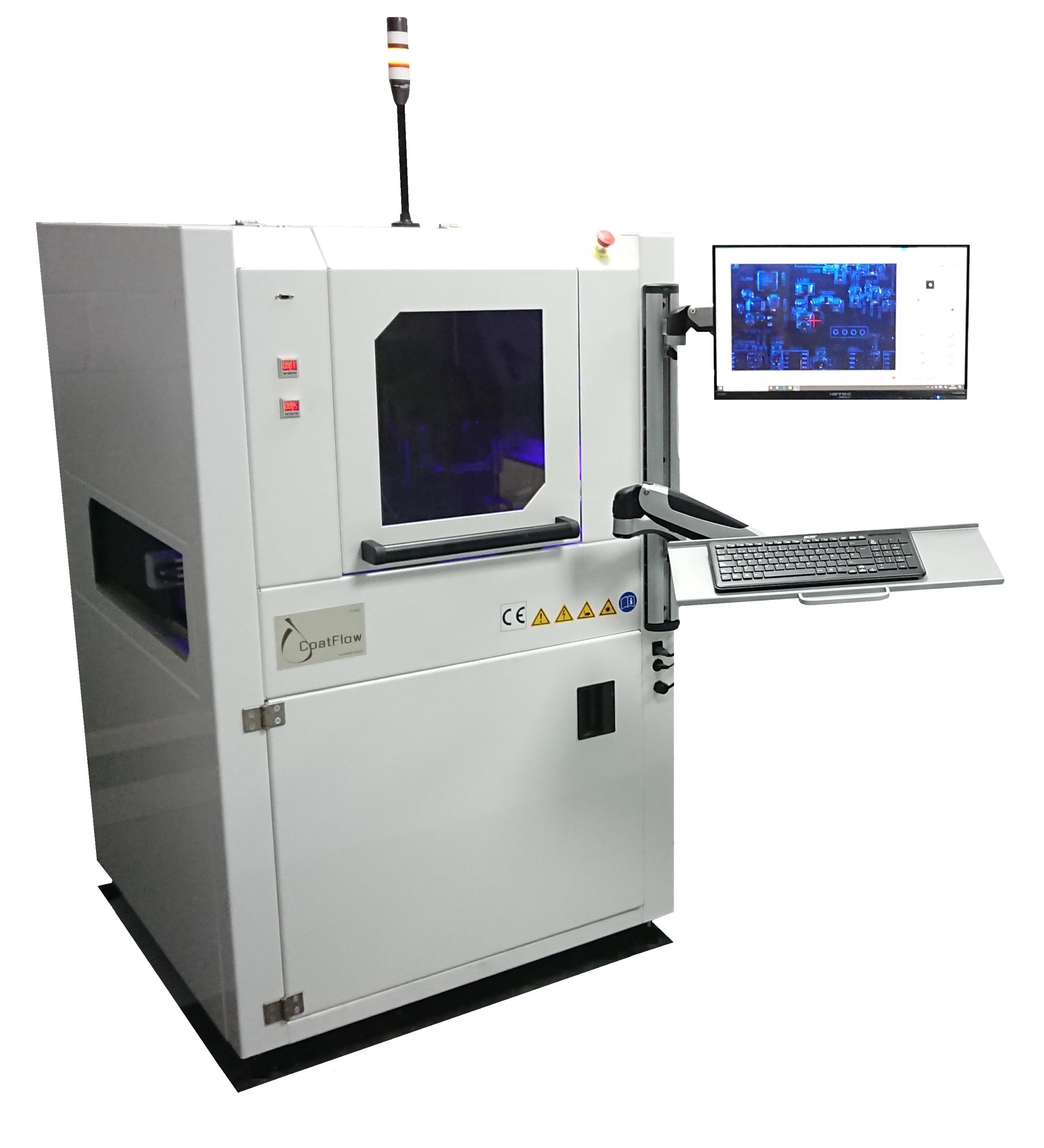

During 2019 the Weymouth site took delivery of an ERSA ECOSELECT 4 Selective Soldering system. The project to evaluate suitable systems started the previous year and was headed by Engineering Manager Tom Troughton.

Tom explains their application in detail – “we have a number of PCBAs that have a large thermal mass and with our existing equipment, preheating in an oven was required in order to achieve the required barrel fill. Due to the design of the existing equipment, 2 programs were also required to solder the different components on the PCBA. Having completed trials on the ERSA ECOSELECT 4, we established that not only was no offline preheating required with this machine, but also only one program was required to successfully solder all the components. This significantly reduces cycle time and therefore will increase capacity in our selective soldering cell. Additionally we were able to demonstrate during trials that the ERSA ECOSELECT 4 could solder a large PCBA that is currently hand soldered due to the board length being outside of our existing equipment’s capability”.

Ultra considered selective soldering systems from 3 different manufacturers during their due diligence process but ultimately, the ECOSELECT 4 was the machine of choice due to the available preheating and over solder pot heating options, as well as the capability to handle large format PCBAs such as backplanes. In addition, due to the dual solder pots, changeover from leaded to lead free solder takes minutes, instead of hours.

Now that the machine has been in use for some months Tom gives his appraisal of how it is performing. “Ultra Electronics CEMS have transferred a number of products over to the ERSA ECOSELECT 4 and found that generating new programs is a very straightforward process, using either ODB++ or an image of the PCB. We have also processed a number of complex NPIs through the machine and have been very pleased with the results achieved”.