Schunk PCB Depanelling

Two Concepts for the complete Spectrum of Depanelling Technology

Increasing speed, maximal accuracy – ongoing advancements in PCB technology mean manufacturers of electronic modules continually face new challenges, which in turn place more demands on accurate and safe board separation. Its performance at the end of each modern production process is decisive for efficiency and productivity.

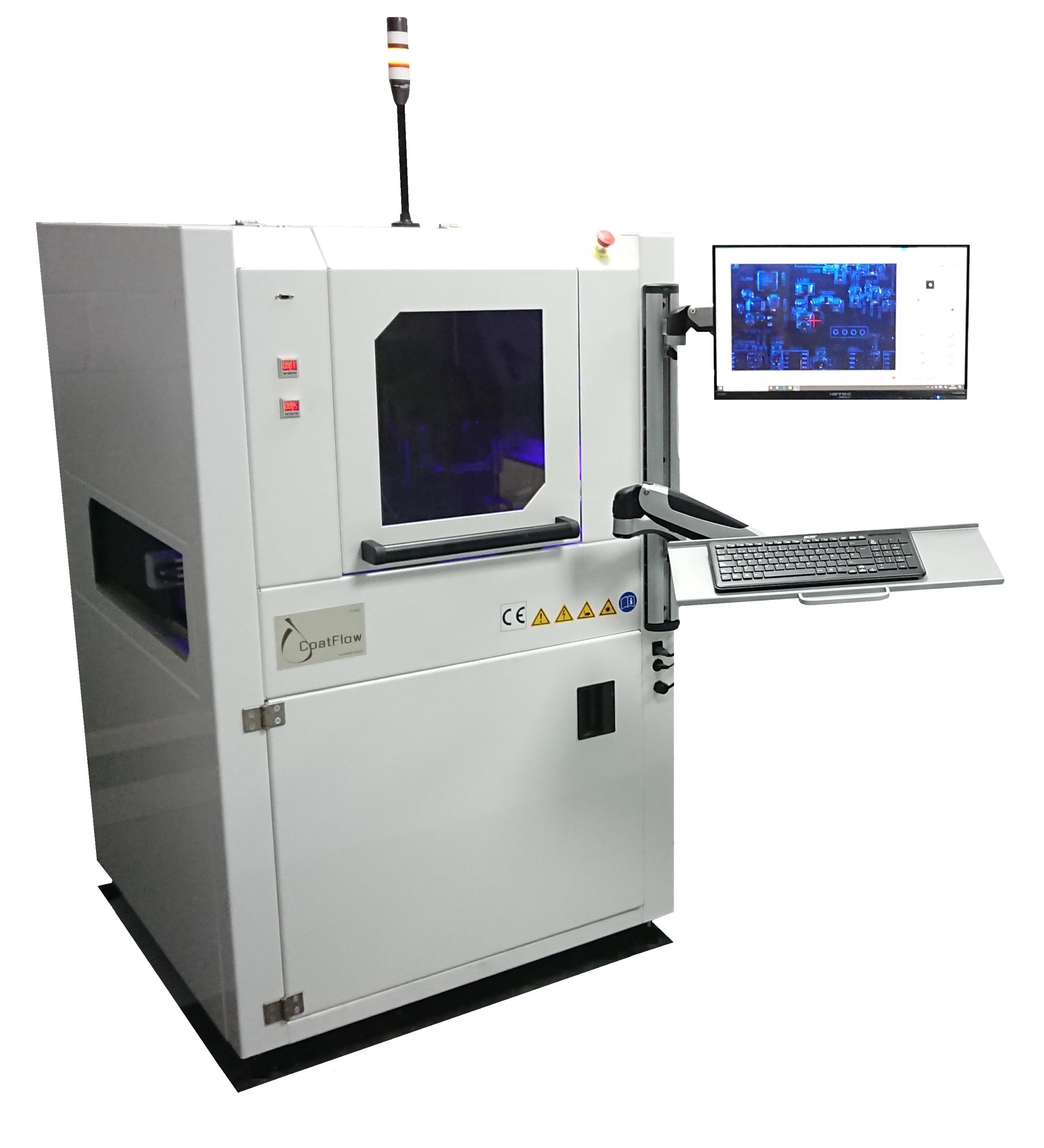

The flexible universal depaneling machines from SCHUNK set new standards with precision, speed, and process stability for the entire spectrum of customer requirements. The cutting is performed by using either a sawing disc or a milling bit – with low-stress impact, efficiently, and without damaging the components unlike conventional cutting processes.

Machine enquiry

- OVERVIEW

UNSURPASSED ACCURACY AND PERFORMANCE FROM SCHUNK

Very precise milling contours by means of high positioning accuracy (±0.02 mm) of the axes and the precise workpiece holder. Due to the highly dynamic linear motors, SCHUNK depaneling machines achieve an approximately 50% higher throughput than comparable machines of the competitors.

Gripping of several individual PCBs in the panel with a modular multi-gripper, consisting of several PGN-plus grippers, followed by detaching or placing it in the following process in a programmed angular position. Transfer of pneumatic and the sensor signals for rotation of the ERD torque module is performed by a rotary feed-through.