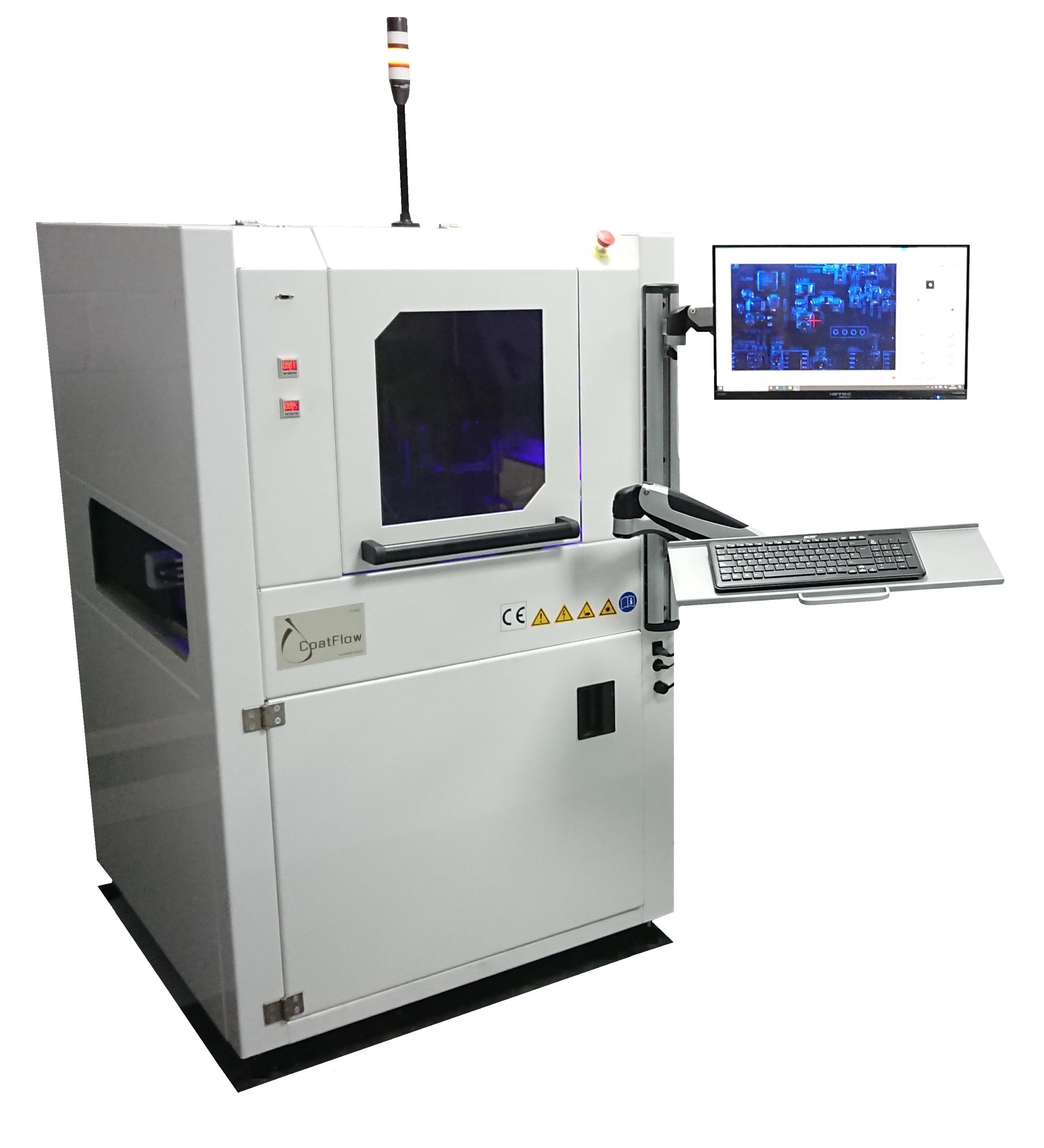

MAX Vacuum Sealing m/c

Vacuum sealing machines made from high grade stainless steel, using high performance vacuum pumps with a long history of reliability.

Re-sealing your components immediately after use reduces the possibility of moisture ingress and ultimately improves the likelihood of problem free processing thereafter.

Machine enquiry

- OVERVIEW

The MAX system is a simple vacuum chamber controlled by a vacuum run time and bag sealing time indicator allowing for differing products and sealing different materials.

Features

- Internal Chamber Dimensions: 320 X 360 X 125 mm

- Seal Length: 320mm

- External Dimensions: 520 X 365 X 350 mm

- Connection: Single phase 230. 50Hz

- Robust vacuum Pump

- Weight: 48Kg

- Other Sizes Are Available On Request

More detail

Our Z 2000 digital control enables the following parameters to be set: vacuum, gas and sealing time. The oxygen content can be reduced in a controlled manner. The memory function enables simple operation and guarantees

Construction

The focus of the construction is on making our machines as easy to clean as possible. The machines are made from stainless steel. The vacuum chambers are deep-drawn and the sealing systems are wireless.

Sealing system

Our high-pressure sealing systems are suitable for all conventional vacuum bags. The increased contact pressure and double sealing ensure identical results even with stronger bag types. In order to prevent unnecessary contamination with germs, the excess bag length can be removed if desired. The sealing systems can be activated individually.

Maintenance program

In order to reduce your maintenance costs and help prevent down-times due to maintenance work, a particular focus has been placed on maintenance-friendly design. Individual components are easily accessible and clearly visible. A service program guarantees a long service life for your vacuum pump.