LM-901 Modular Manual Placement System

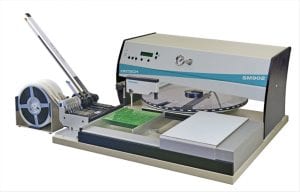

For prototyping or small-series production, the modular FRITSCH LM systems are ideal partners.

Machine enquiry

- OVERVIEW

- VIDEOS

LM901 Manual Palcement System

The LM 901 is the entry model of our modular-built systems. Besides the LM 900 functionality, it can be extended with axis brakes, dispensers and optical support systems for component placing.

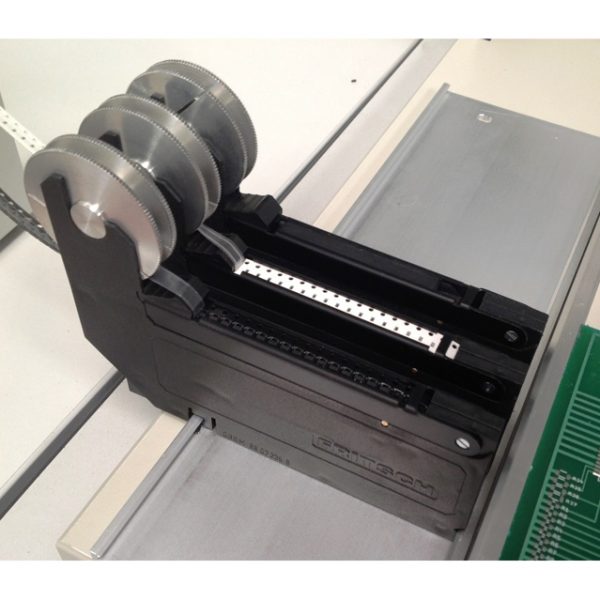

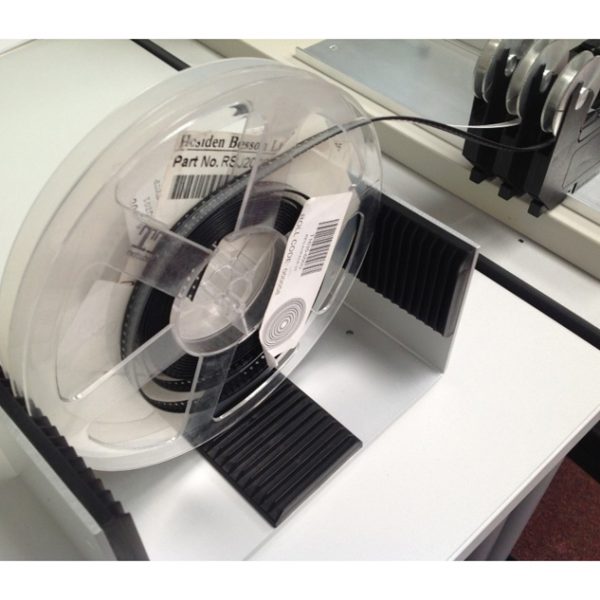

With this systems, the pick & place process can be implemented. Depending on the extent of the LM-system, the user can assemble Chip devices , SO and FP components.

The LM 901 supports the whole dispensing-/ Pick&Place – process, from supplying the solder paste or glue to placing standard, Fine-Pitch or BGA components.

To ensure high flexibility, the LM 901 can be upgraded to a semi-automatic manipulator and therefore fills the gap to our SM series systems.

The software of the LM systems releases the user from reading project or placing lists. It also shows the pickup and place position and more information on the current component. By this, a highly secure pick&place process is reached. To remain flexible in daily work, existing CAD data can be imported into the software.

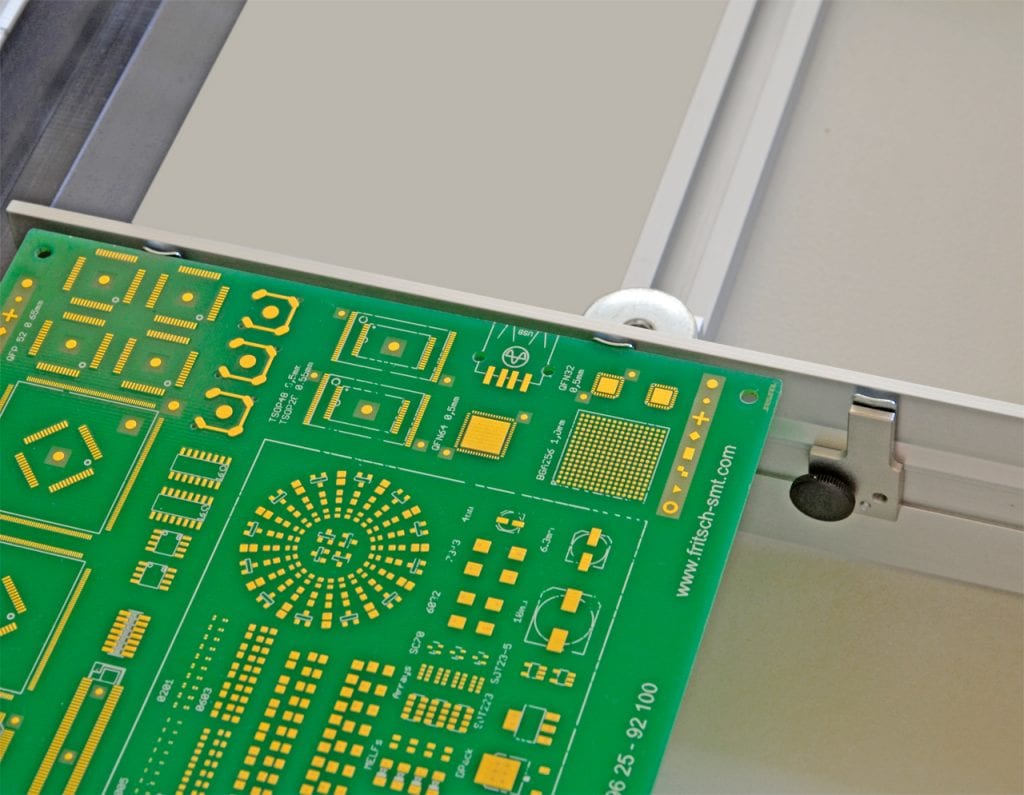

Maximum standard board handling – 260mm x 410mm

Universal circuit board holder

The universal circuit board holder retains single- and double-sided boards safely using adjustable, elastic holding fingers (see picture above). Large circuit boards can be handled on demand.

If you need a custom circuit board holder, our development department is pleased to realize this special task for you.

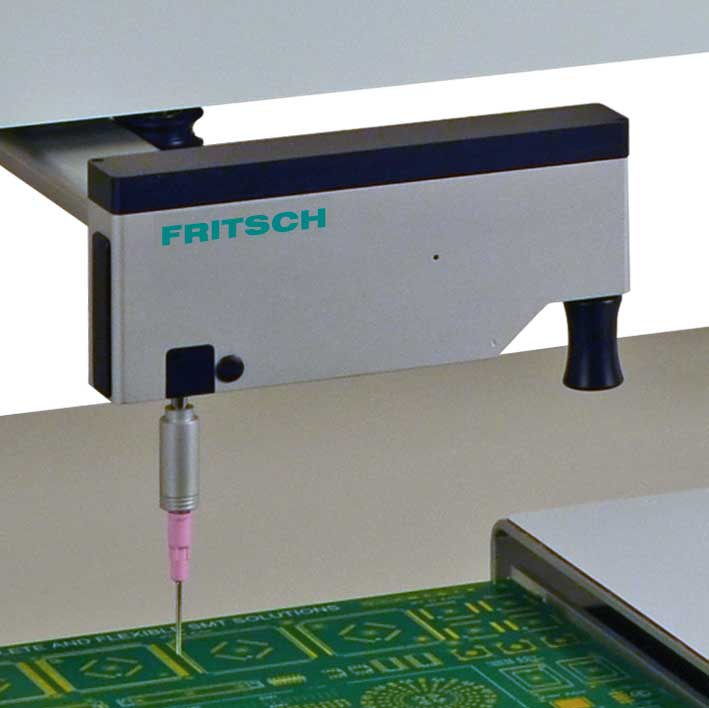

Camera

With a camera attached to the assembly head, you can view the whole Pick & Place process – magnified on a monitor.

Thus even the smallest parts like 0402 and 0.5mm pitch devices can be placed exactly. Another benefit of the camera is the possible documentation of the process by saving single picture frames to the hard-disk of an attached PC.

Erganomics

The unequaled guiding system of the assembly head results in comfortable and fatigue-free daily work. All of the control elements are arranged logically and ergonomically, which assists the user in the best possible way.

A relocatable hand-rest is already included in the standard version of the machines.

Assembly head

The assembly head is equipped with a patented constant-force trapezoidal spring. The spring tension is distributed equally over the total range of the Z-axis.

The whole assembly head is maintenance-free.

Component flipping

is always a problem with manual systems – Click to see Flip tray video