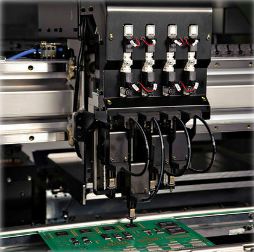

i-Pulse M20 placement

In keeping with the I-Pulse philosophy of designing flexible, high specification SMT manufacturing centres, the new M20 series is targeting both current and future manufacturing requirements.

The M20 is addressing the requirements of high feeder capacity, production flexibility and the increasing demands of new component technology and market demands.

The highly flexible M20 is available with a range of head configurations to suit capacity and technology demands. The ability to configure the M20 with head variants to handle standard SMT, odd form, plus the removable hybrid dispense option makes the M20 a uniquely flexible mounter.

For Smaller option See:- i-Pulse M10

Machine enquiry

- OVERVIEW

- VIDEOS

The range of removable feeder bank and tray handling options allows fast product change over utilising the intelligent feeder software. The M20 can offer the user up to 180 x 8 mm feeder position either fixed or removable feeder banks.

All I-Pulse mounters can link directly to the unique Iemme Lzero series Intelligent component storage cabinets providing users with a fully networked production and component kitting function, further enhancing the speed of job change and with the added benefit of ‘closed loop stock control’ on the shop floor.

Features

- Ultra Large board capability for LED lighting applications up to 1,800 mm.

- Board warp detection.

- Component range – 01005 up to 120L x 90W x 30 mm high.

- High Feeder capacity – up to 180 x 8mm feeders.

- Fast change Hybrid dispense capability.

- Multiple head options – Standard, High Precision and High Performance.

- Fully controllable placement force.

I-Pulse M20 is a truly future proof and flexible system designed for the demands of today and future of SMT manufacturing.