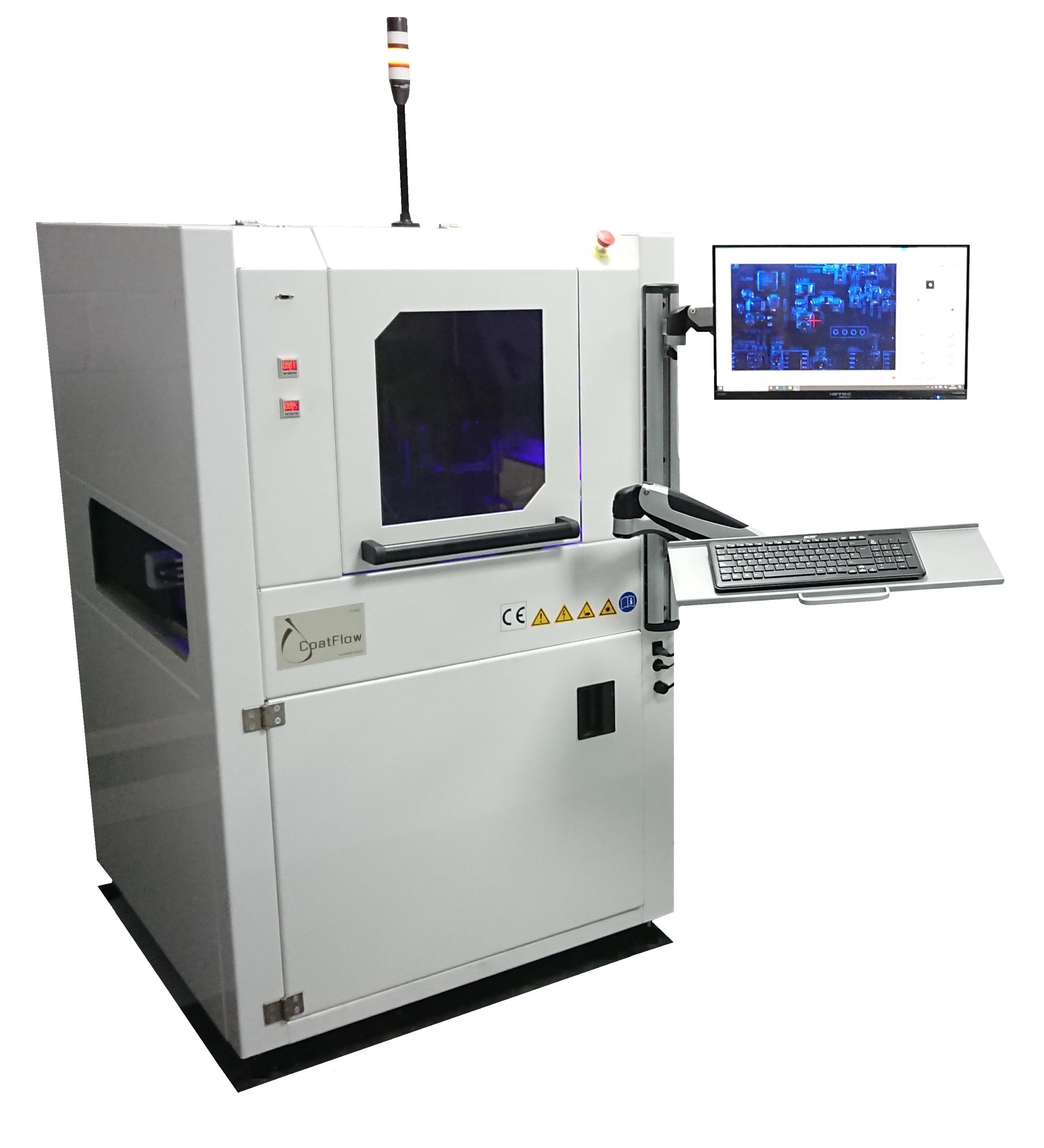

Flash-off Station for CF395-IL

- Inspection station specially designed for pcb´s inspection after coating process.

- black and white light for automatic inspection. Automatic switching.

- security glass in cover.

- two ways of work: inspection and flush off (evaporation of solvents and bubbles reduction before the ir oven)

- inspection mode: automatically stop each plate in the central area for inspection with black light. When this is correct. Operator can press button and continue to the oven.

- flush off mode or evaporation: we will create a buffer where the pcb´s will enter after the coating machine. The distance between pcb´s and the displacement speed are configurable by screen

- robust construction to avoid unwanted movements and vibrations.

- touch screen allows to control the work modes and see the status in

- Real time of the entire system. All configurations are performed by software.

- totally smema compatible.

- motor traction system step by stepper motorswith steel chain.

- interior made with stainless steel and aluminum for easy cleaning and good protection against solvents and aggressive liquids

×

Machine enquiry

- OVERVIEW