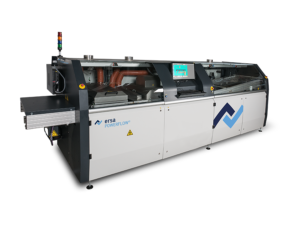

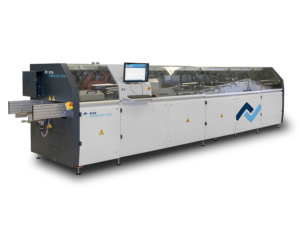

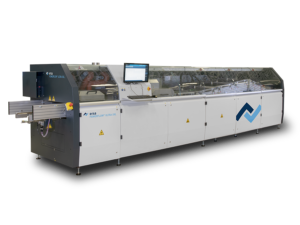

Ersa Powerflow PRO

Compact full tunnel wave soldering system for cost-optimized wave soldering

- Modular, flexible and individually expandable preheating concept variably configurable in length and power

- Award-winning database-based operating software ERSASOFT 5 > Ready for Industry 4.0

- Finger and frame transport with different working widths

Machine enquiry

- OVERVIEW

With the Ersa nitrogen-atmosphere wave soldering system POWERFLOW PRO, Ersa presents a basic system for demanding, cost-optimized wave soldering processes. The system focuses on proven machine concepts and offer future oriented and innovative solutions, which provides to its user an optimized process.

The easily accessible fluxer area offers excellent maintainability. With the upper and lower pre-heaters, the well-insulated tunnel ensures that the boards are completely heated through, even with high-mass assemblies.

The coated solder module offers, on account of the availability of different wave formers, for each application the best solder quality and a high degree of repeatability. Nitrogen control with the rest-oxygen monitor maintains the O2 level in the nitrogen atmosphere level at the desired level.

Options

- Finger transport

- Working width up to 330 / 400 / 458 mm

- Spray monitoring on the fluxer

- Extendable, maintenance-friendly fluxing unit

- Quick-change spray head

- Convection heater

- Nitrogen control with analyzer

- Touchscreen