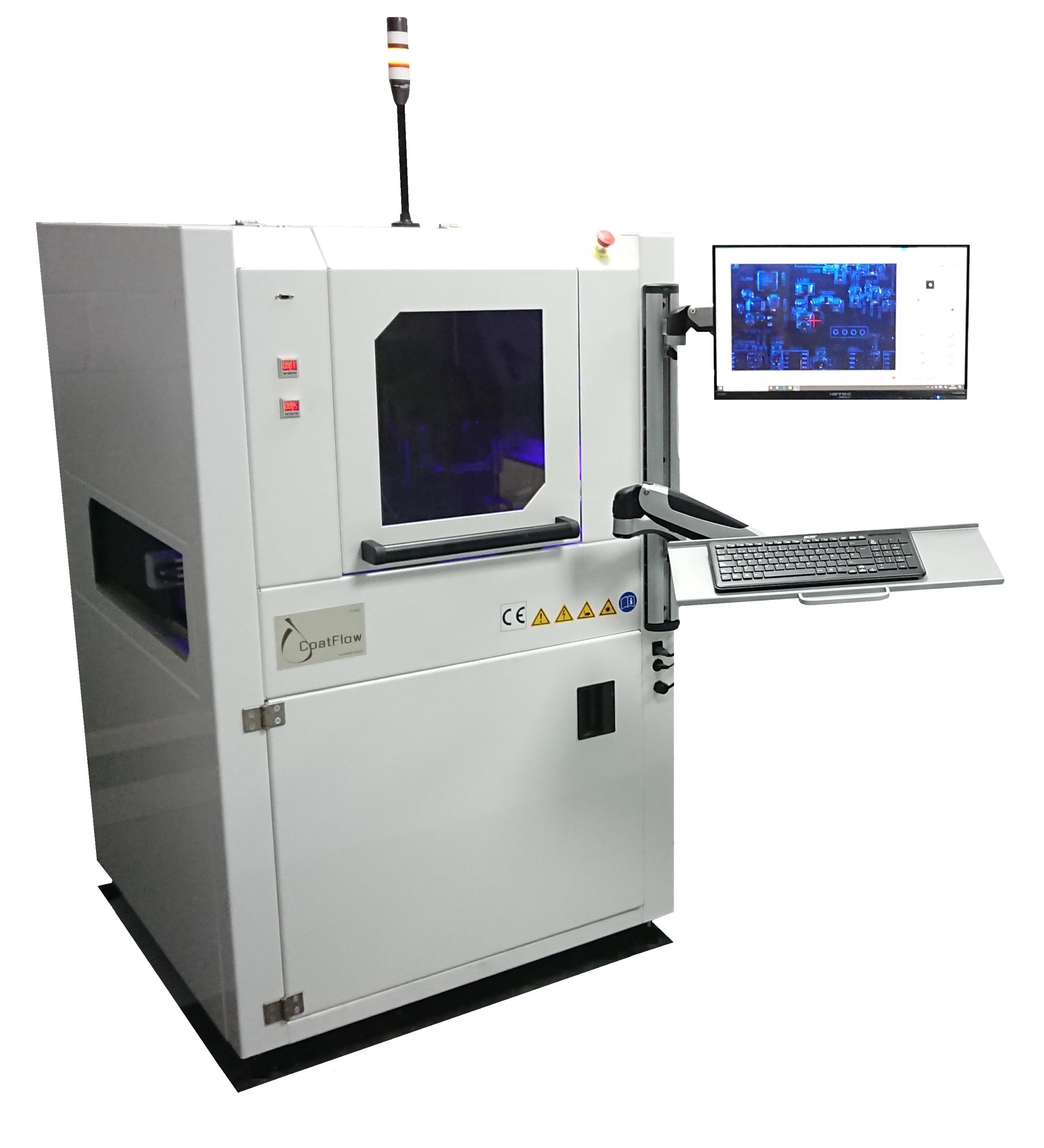

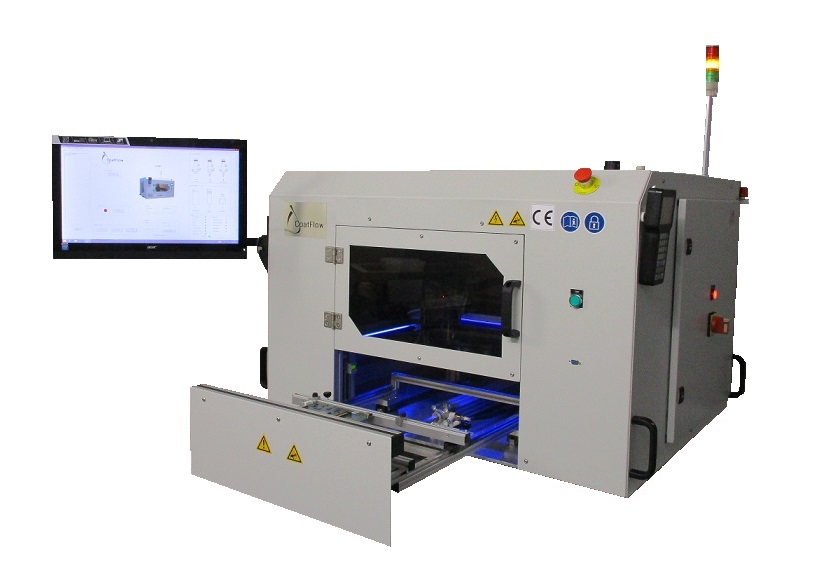

CF440 benchtop batch production system

×

Machine enquiry

- OVERVIEW

Motion:

- ball screwdriven by servo motors

- x, y speed: 0 a 900 mm/sg

- z speed: 0 a 900 mm/sg

- positional accuracy: 0.005 mm

- positional precision: 0.01 mm

Working area:

- standard 500x500x100 mm (with purge and park cups 500×465 mm)

- with teaching camera the programming area is reduced depending on the valve configuration (ask about final area)

Pcb´s suport:

- adjustable fixture for boards

- component clearance up to 60 mm (below and above). If auto drawer installed belowclearance less than 50 mm

Control:

- laptop pc (windows 10 included)

Software:

- coatcontrol pro 2.0 ® incluided

- pathcoat ® offline optional

Accessories included:

- automatic park and purge system

- automatic control of valve parameters

- 5th-axis tilt in needle or microspray valve

- three-colours and buzzer light tower

- 5 liters stainless steel pressure tank with low level sensor

- 6 oz-cartridgewith low level sensor

- syringes adaptor 30 and 55 cc

Valves configuration

- 2 or 3 valves: precision spray, microspray, needle, rotary etc.

- a full range of valves is available to cover all dispensing and coating demands. Coatings, gaskets, fillings, and other kind of processes are also possible.

Power supply

- 110/230v 1 fuse. 10a max

Security

- emergency button

- security interlocks in door

- exhaust pump sensor

- spray sensor control

- CE certification