Extra Eye – AOI & FAI

Auto-Optical Inspection (AOI)

First Article Inspection (FAI)

Now Two Systems in One

lowest cost camera based system available that does not require a dedicated technician to program or operate.

Auto inspection achieved within minutes from receipt of basic information, not hours.

Automatically generates a full report.

×

Machine enquiry

- OVERVIEW

Common Features:

- Camera Based system

- Fiducial Correction

- Does not require a dedicated Technician to program or operate

- Professional report generation for full tracability

- SPC output to Excel

- Self teach coordinates if no XY data is available

- Multi-panel with scrap circuit option

FAI: (First Article Inspection)

- Designed to aid True First Article Inspection

- Proven to improve efficiency by up to 70% when compared to traditional methods of manual Inspection

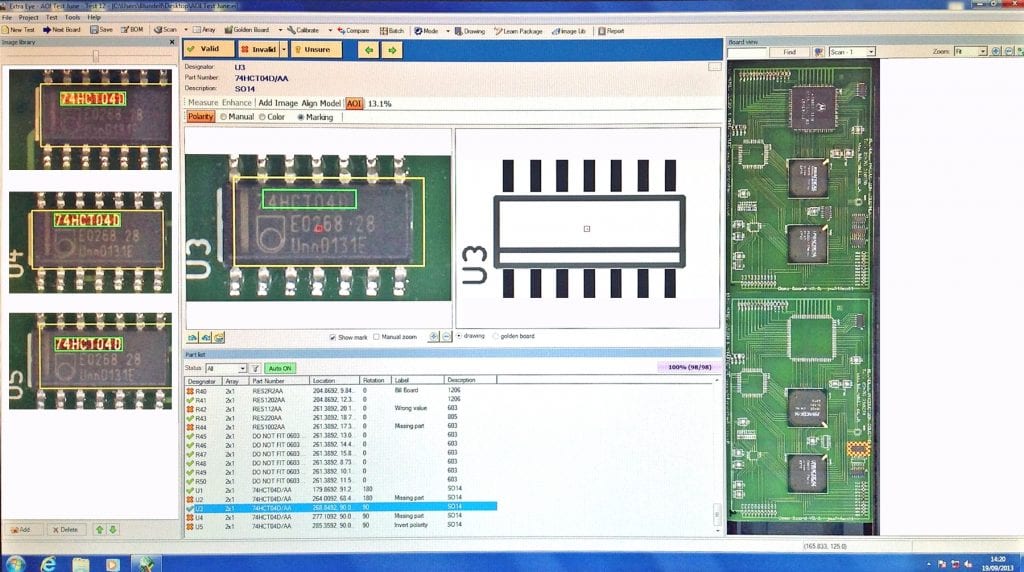

- Brings together the line item from the BOM, image of placed part and drawing reference in a single screen shot

AOI: (Automatic Optical Inspection)

- Verifies Part Number stored Library Images against actual fitted parts: 30 seconds for 1500 components

- Checks for presence, polarity, value, billboard, tombstone, skewed placement

- Choice of algorithm with sensitivity adjustment; OCR or Colour

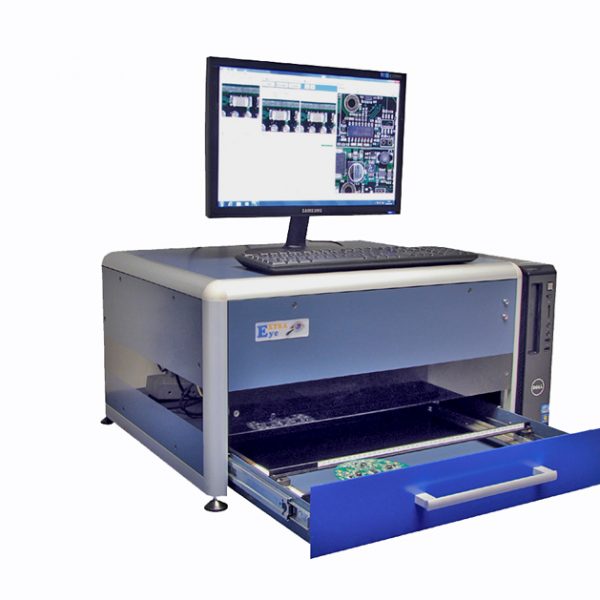

| Model | X-3000 Model-X | X-4000 |

|---|---|---|

| Max PCB size | 380 x 450 (mm) | 500×540 (mm) |

| Max component heighT | 50 (mm) | 50 (mm) |

| Image resolution | 1100 DPI | 1100 DPI |

| Dimensions | 680x575x380 (mm) | 770x730x380 (mm) |

| Weight:X-Y Axis camera system | 24 (kg)240VAC | 32 (kg)Window 7+ |