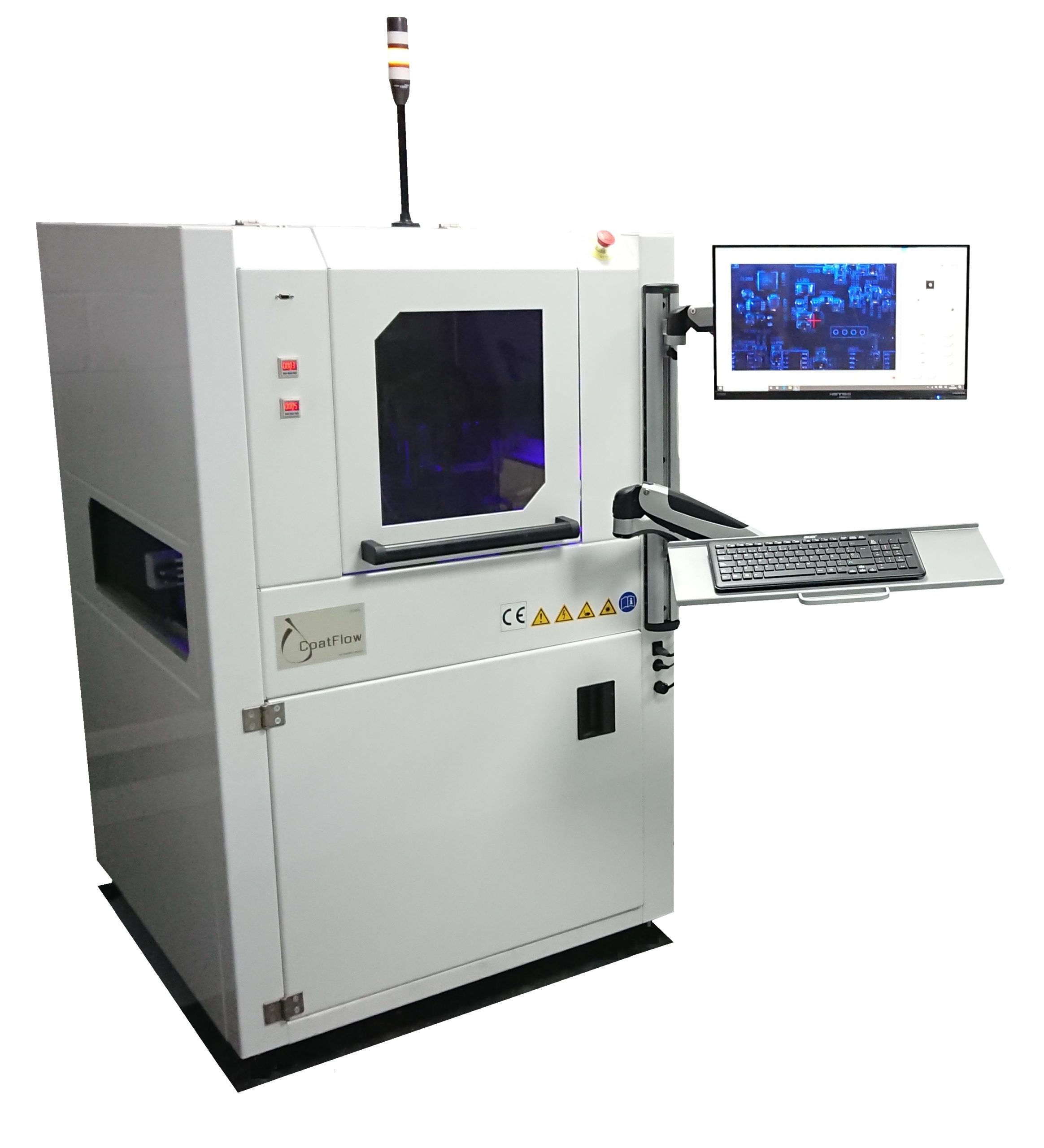

SMT Placement - Pick and Place Machine

Our portfolio of pick and place machine equipment covers a range of different SMT pick and place machine options to help you find the best suited to you and your company requirements. Blundell supply a range of options, from manual hand placement, all the way through to high speed pick and place systems, and everything in between. You can therefore be assured that we will have a pick and place machine which is suitable for you.

Our distributors are leaders within the field of SMT pick and place machinery, offering a wide range of quality pick and place machine options, including 3D MID placement, and flexible circuit SMT placement.

Our suppliers at Fritsch offer everything from manual pick and place machine options, down to mid-volume intelligent fully automated SMT machines. T.W.S. SMT equipment is suitable for entry level automated batch assembly. i-Pulse/Yamaha supply medium to high-end, high speed no compromise fully integrated systems. There is a pick and place machine to suit almost all requirements.

Browse Blundell’s SMT machine range, and please contact us for any further information relating to pick and place machines.