Fume Extraction

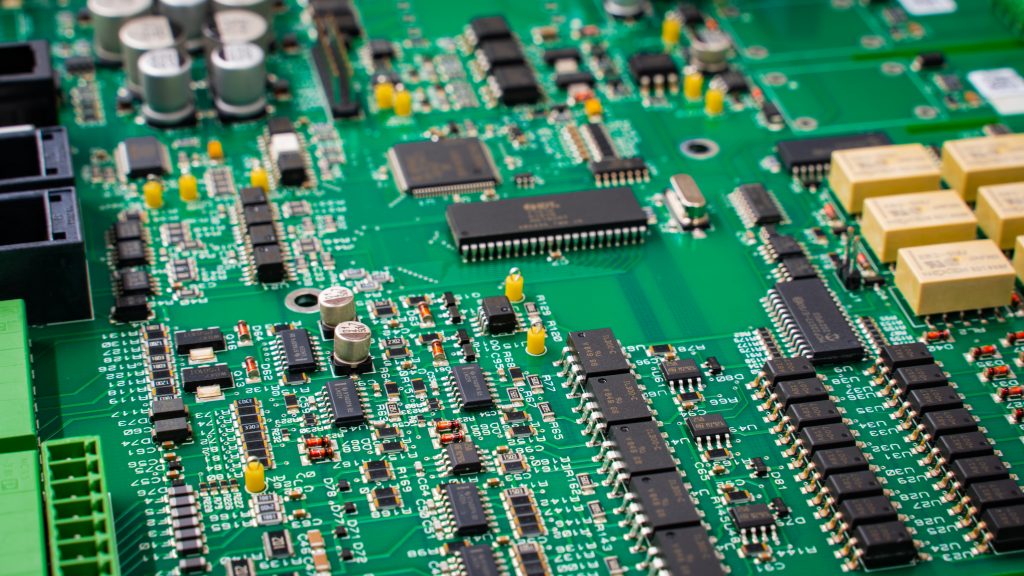

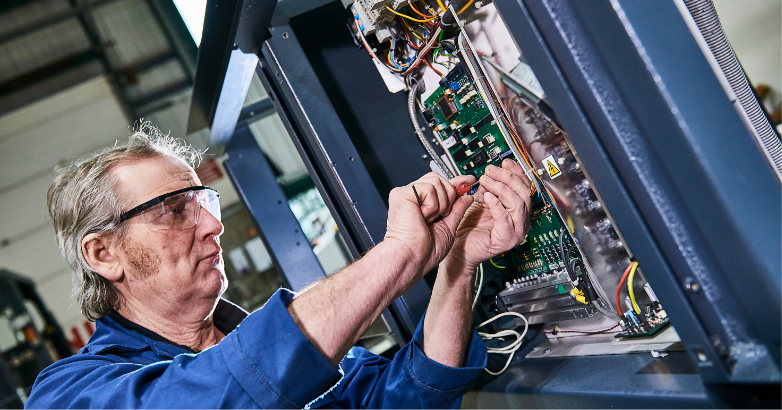

Blundell supply a wide variety of solder fume extractor machinery to extract any hazardous dust and fumes caused by the soldering process. Fumes that are created during soldering have been linked to asthma and serious carcinogenic diseases amongst workers, so it’s important that companies invest in quality solder fume extractor equipment that helps to combat this. Using a solder fume extractor can help to protect your employees from risks to their health.

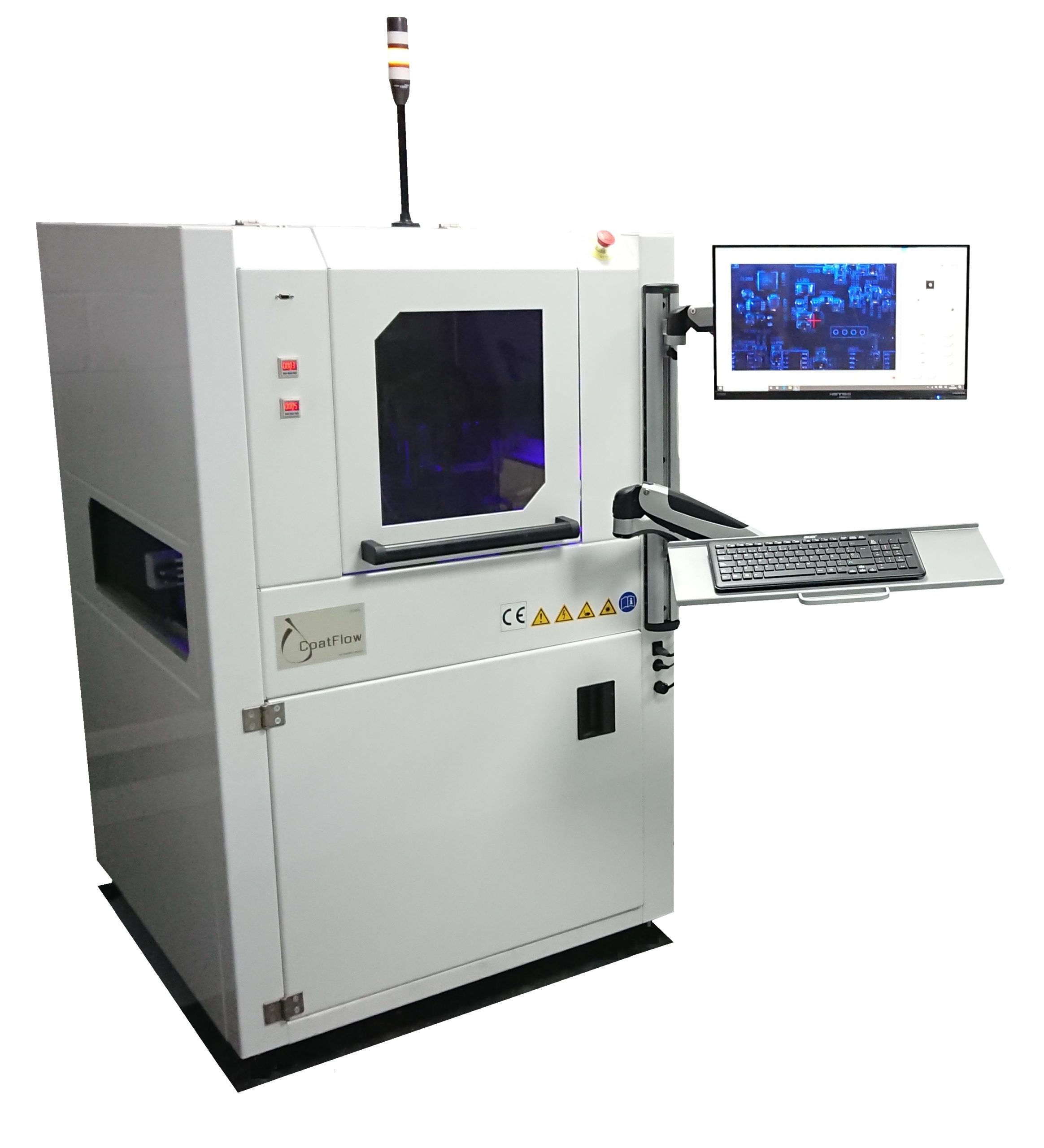

The solder fume extractor range offered by Blundell can be used to protect one or multiple users at a time, making them ideal for production lines and wave soldering. Browse our selection of extractors to find the right product for you, or contact us for more information.