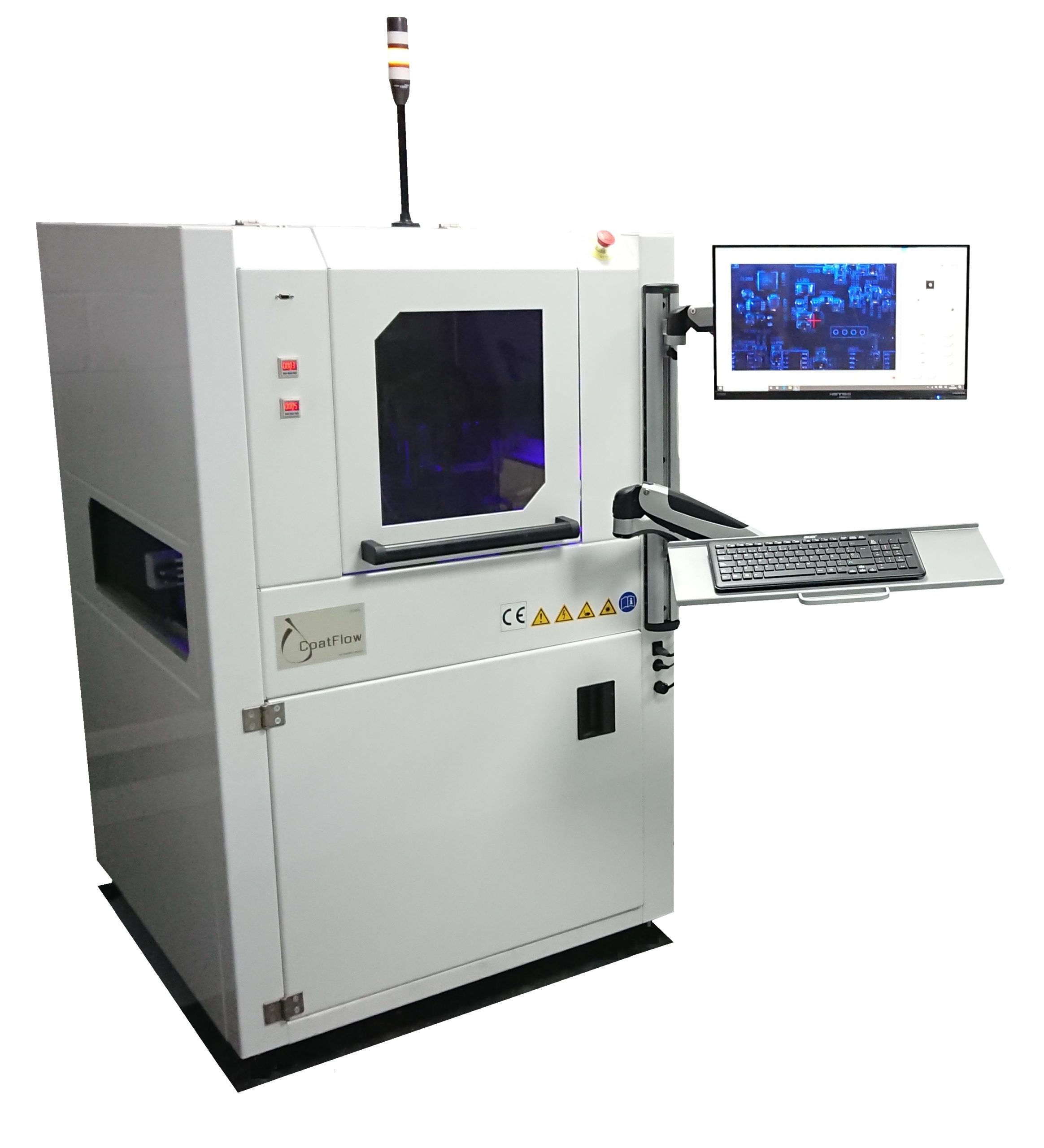

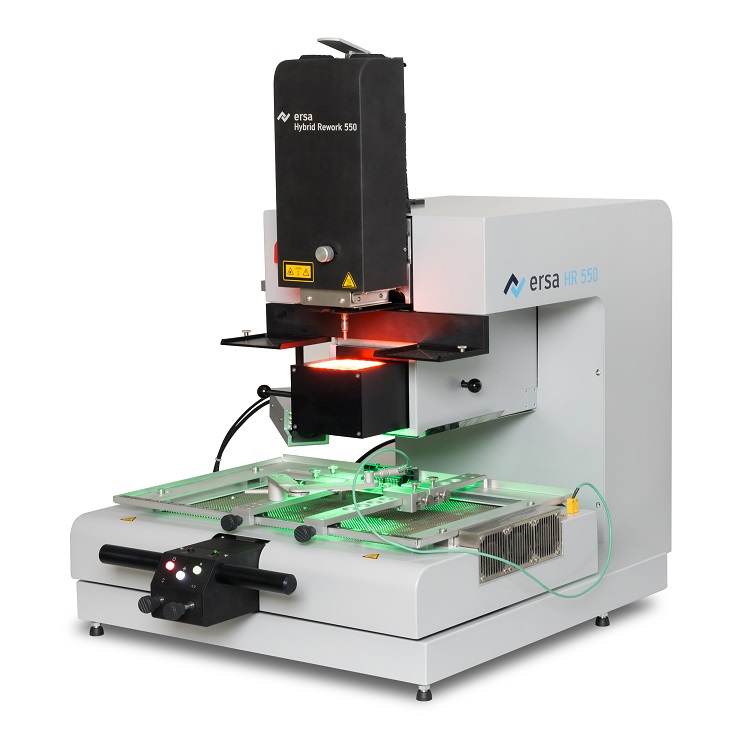

ERSA HR550

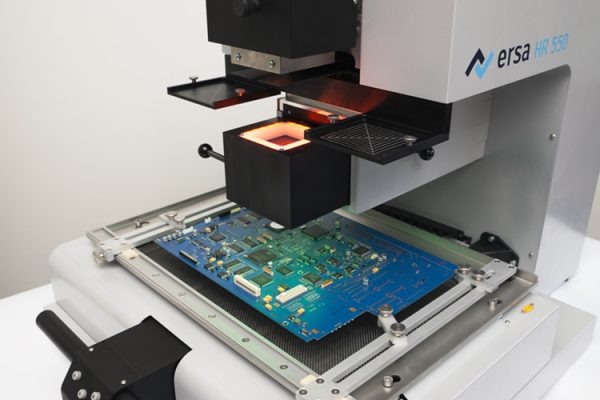

The ERSA HR550 is a powerful Hybrid Rework System, 3.9 KW.

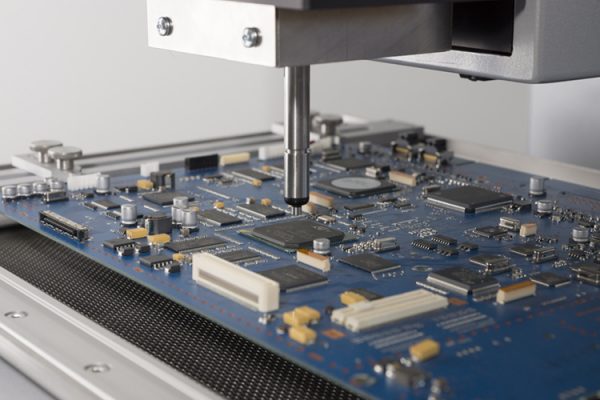

Desoldering, placement and soldering of all types of surface mounted devices (SMD) – up to 70 x 70 mm: BGA, metallic BGA, CGA, BGA socket, QFP, PLCC, MLF and miniature components with an edge length of min. 0.2 x 0.4 mm.

Features of the Ersa HR550

Highly efficient 1.500 hybrid heating head

Large-area IR bottom heating in 3 heating zones (2.400 W)

Integrated vacuum pipette for component removal and placement

Highly accurate placement with integrated force sensor

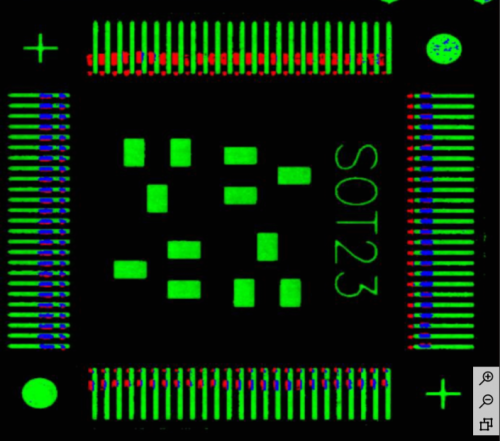

Enhanced Visual Assistant (EVA)

Computer aided component placement

Process control and documentation via software HRSoft 2

Suitable for the use of the Dip&Print Station

These variety of features make the Ersa HR550 an excellent piece of equipment.

Are you looking for more information about the Ersa HR550? Please contact Blundell today and one of our knowledgeable team will be able to advise further.

Machine enquiry

- OVERVIEW

- DOWNLOADS

- VIDEOS

| Specifications | |

|---|---|

| Dimensions (W x D x H) in mm | 573 x 765 x 545/747 (heating head down/up) |

| Weight in kg | 76 |

| Antistatic Design (y/n | Yes |

| Power Rating in W | 3,900 |

| Nominal voltage in V AC | 230 |

| Upper heating Hybrid emitter | (900 + 600 W), 70 x 70 mm |

| Lower heating IR emitter | (3 x 800 W), 390 x 270 mm |

| PCB size in mm | from 20 x 20 to 382 x 300 (+x) |

| Component size in mm | from 0.5 x 0.5 to 70 x 70 |

| Operation | Windows PC |

| Test symbol | CE |